3D printing risks

“We are facing chronic pollution”

Toxic emissions

Nanoparticles & VOCs

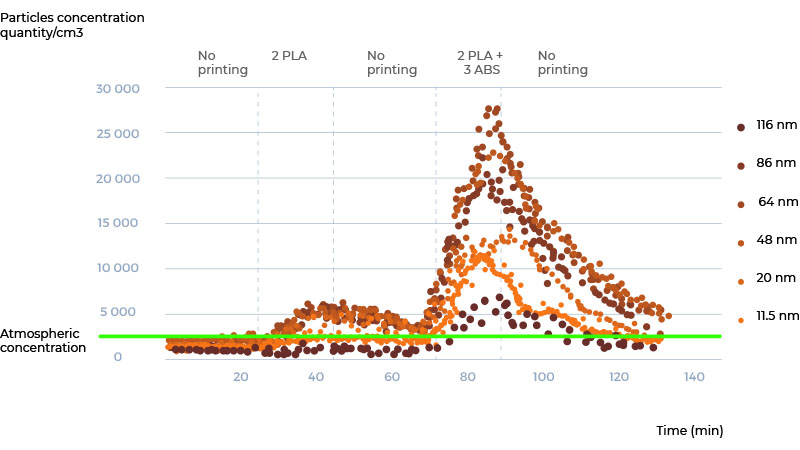

Studies have shown high nanoparticle emissions from 10 to 100nm and significant production of VOCs from the filaments fusion. You might breathe harmful air in the presence of 3D printers, and in a repetitive way. That is chronic pollution with a long-term effect on your health, which you can prevent with safety features.

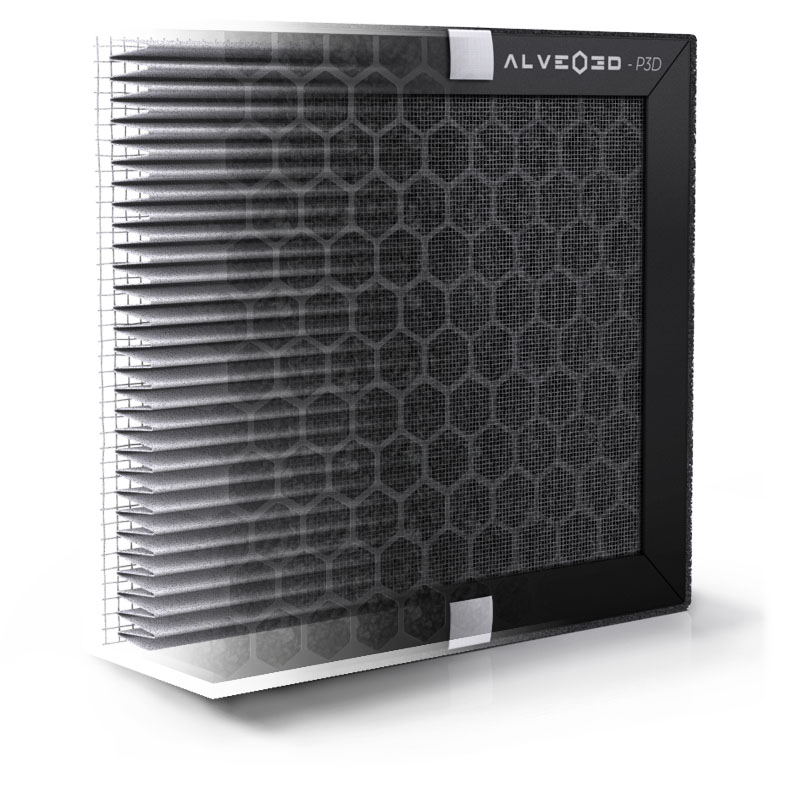

Filter

HEPA & Activated carbon

The P3D range filter received special attention to strictly follow the requirements of air filtering for nanoparticles under 100 nm and provide 98% efficiency. In order to neutralize odors and symptoms of irritation, a specific activated carbon was selected.

Alveo3D catalogue

Design & manufacturing in France

AlveoONE & R

Air filtering system for 3D Printer FDM

Starting from 79,99€, in kit or assembled

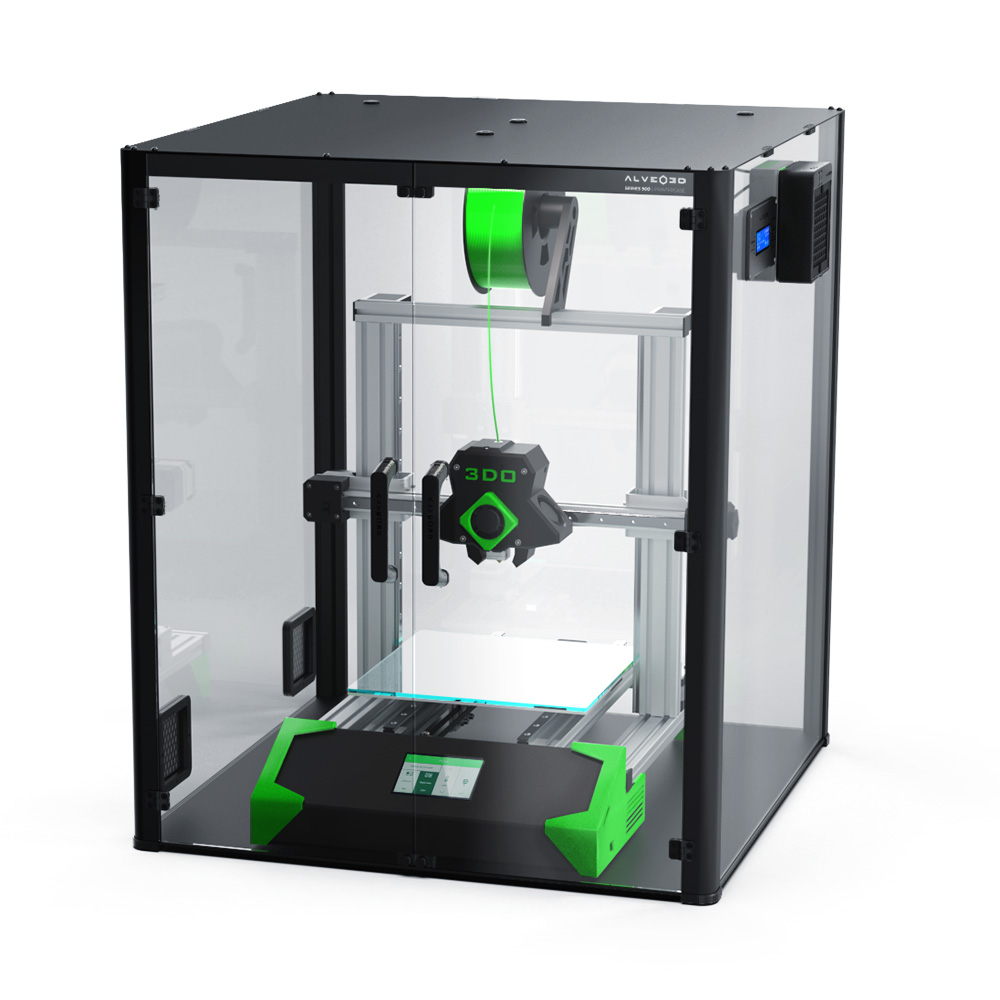

PrinterCase

Air filtering system mountable on an enclosure

From €696,00 incl. VAT – available in 3 sizes

Custom-sized enclosure

Customized enclosures for desktop 3D printer (SLA+FDM)

With industrial quality and volume to 1 m3

AlveoPRO

Professional 3D printer fume extractor

3D printer fume extractor with M100 HEPA14 and activated carbon (1500h+)

Global safety solution

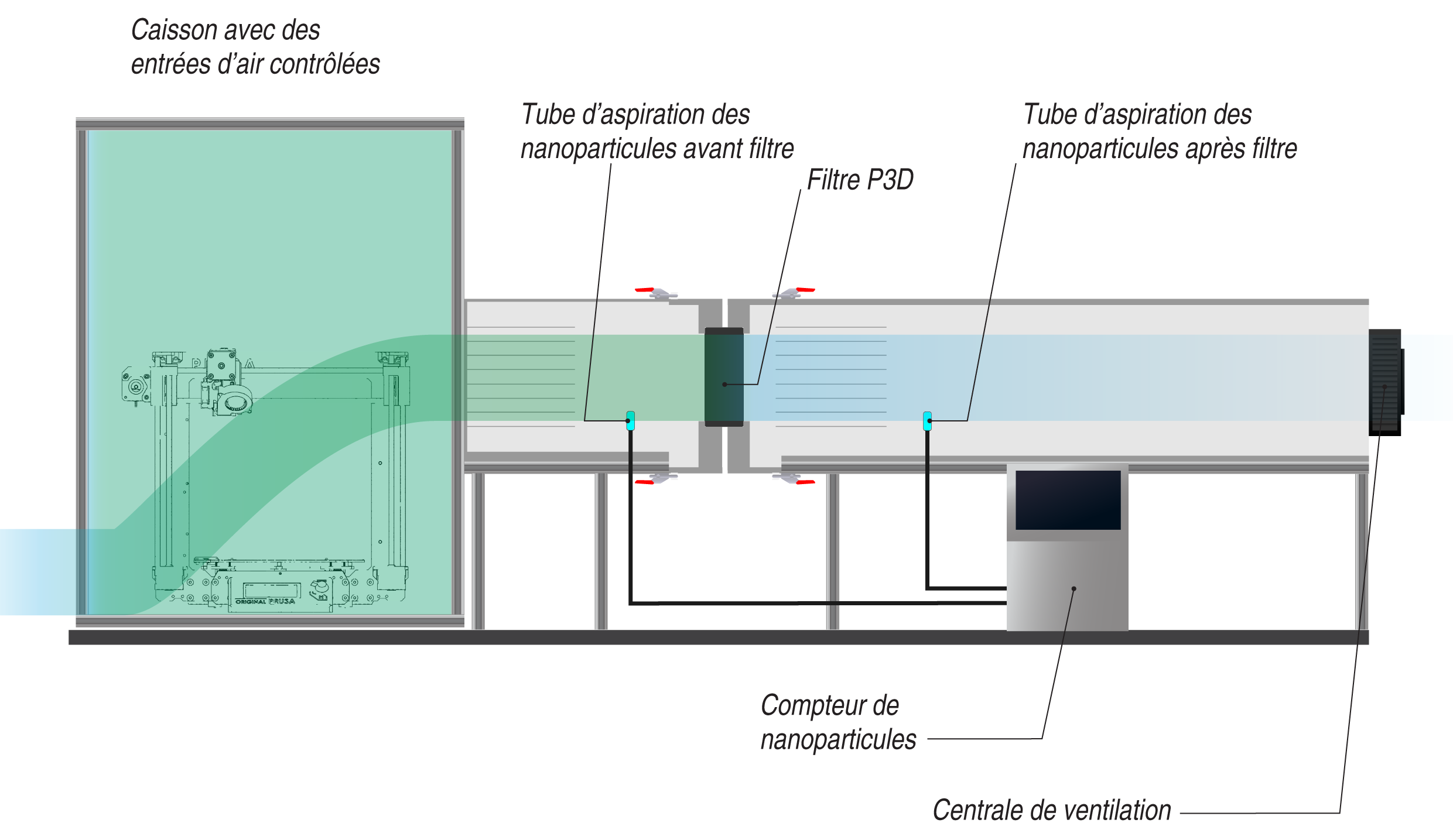

Combining AlveoONE air filtering with an industrial enclosure provides an ideal environment for your 3D printer in order to improve your prints while limiting the warping effect and protect you from harmful emissions.

Melting plastic: a good idea without any protection?

Release of nanoparticles and VOCs

A 3D printer enclosure is necessary to complete beautiful prints without the warping effect. An enclosure can stabilize the temperature and protect the printing zone from draughts. However, inside the enclosure, the harmful emissions will be concentrated at the printing and require air extraction or constant filtering.

Solution for additive manufacturing professionals and printer manufacturers

Design of customized safety solutions

Integrate our solutions into your professional 3D printers

– 3D printer manufacturers –

Your clients ask us to protect their operators and machines with enclosures and efficient filters. Incorporate an Alveo3D directly on your 3D printer to get a reputed and efficient air filtering system.

Design and production of compact customised filters

– All industrial field –

With the flexibility of additive manufacturing, we are able to design custom air filters. We can adjust filter specifications to catch targeted pollutants and keep the required airflow.

Particle emissions testing for 3D printing filaments

– All of filaments –

We offer particle emission testing services for 3D printing filaments. We measure particle concentrations and filter efficiency, ensuring compliance with health and safety standards.

How harmful are emissions from 3D printers?

Press Review

Alveo3D filter boxes have been designed to be 3D printed, with ease of use and easy replacement of filter cartridges. They combine a powerful high-pressure fan with a filter cartridge specially designed to combat the harmful emissions of FDM 3D printing…

The growing Chambéry-based start-up develops solutions to protect users from toxic emissions generated by 3D printers. It has raised 103,000 euros to accelerate its development. Filtering out toxic emissions from 3D printers…

Based on this observation and the absence of solutions on the market, a French company, Alveo3D has come up with a particle filtration system for 3D printers…

A simple turnkey solution for 3D printing filtering is this wall-mountable filter. Alveo3D makes a 3D printing filtration unit that will filter out both VOCs and ultrafine particles. Each filter is made of HEPA H13 and activated carbon …

Health and safety hazards of 3D printing

What is the main danger of the 3D printer for the user?

3D printers can be polluting due to the emissions of Volatile Organic Compounds (VOCs) and nanoparticles, especially with certain filaments like ABS. These emissions can be harmful to health, causing neurological, heart problems, or even cancers.

The risks are higher in small, poorly ventilated spaces. It is recommended to use these devices in well-ventilated places and to prefer less toxic filaments like PLA. Research continues to reduce these impacts.

To minimize these emissions and protect the user’s health, the use of an effective filtration system, such as the AlveoONE system, can be an important solution. The AlveoONE filtration system is designed to capture these particles and VOCs, thereby improving air quality in the printing environment and making the use of filaments even safer. This system is particularly recommended when using 3D printers in poorly ventilated spaces or when there is a particular concern regarding indoor air quality.

Does the 3D printer need ventilation?

Yes, ventilation is important when using a 3D printer, especially when printing with certain materials like ABS or PETG. Here’s why ventilation is necessary:

- Fumes: Some 3D printing materials, such as ABS, emit potentially harmful fumes during the printing process. These fumes can include volatile organic compounds (VOCs) and ultrafine particles, which may pose health risks if inhaled in high concentrations.

- Odors: Printing materials can produce strong odors, especially when printing with ABS or certain specialty filaments. Proper ventilation helps to remove these odors from the printing area, creating a more pleasant working environment.

- Air Quality: Ventilation helps to improve overall air quality by reducing the concentration of airborne particles and contaminants. This is particularly important in enclosed spaces where fumes and odors can accumulate.

- Temperature Regulation: Effective ventilation can help to regulate the temperature inside the printing enclosure, preventing overheating and ensuring optimal printing conditions.

Is PLA dangerous to health?

PLA (polylactic acid) is considered one of the safest materials for 3D printing, especially because it is derived from renewable resources such as corn starch and is biodegradable.

However, during 3D printing, even PLA can emit ultrafine particles and volatile organic compounds (VOCs), although generally in smaller amounts than other plastics.

Is PETG fume toxic?

No, PETG itself is often not considered toxic, especially in comparison with other plastics used in 3D printing. PETG is a thermoplastic commonly used for applications requiring greater strength than offered by PLA, including for objects in contact with food or beverages.

However, when heated for 3D printing, PETG, like all plastics, can emit ultrafine particles and volatile organic compounds (VOCs). These emissions can vary depending on temperature and printing conditions but are generally considered less problematic than those from materials like ABS. To minimize any potential exposure, it is advised to use good ventilation when printing with PETG, and the use of filtration systems like AlveoONE can help improve air quality in the printing space.

Is ABS, ASA fume toxic?

Yes, Both ABS and ASA fume are toxic due to the emissions of toxic fumes and VOCs when heated during 3D printing. ABS and his brother ASA (thermoplastic filament) are known to emit more toxic fumes than PLA or PETG when heated. These emissions can include fine particles and VOCs, which can be irritating and potentially harmful, especially in cases of prolonged exposure.

Why is PLA not recyclable?

Although PLA is biodegradable, it does not easily decompose under natural conditions. Moreover, PLA may require specific industrial composting conditions to degrade properly. Its biodegradability does not necessarily make it compatible with traditional plastics recycling processes, hence the difficulties in recycling it within standard recycling systems.

How to clean 3D printer resin?

To clean resin from a 3D printer, it is recommended to use isopropyl alcohol (IPA) or a similar solvent. After printing, remove the printed parts and immerse them in an IPA bath to dissolve the non-polymerized resin. Use gloves and work in a well-ventilated space, as resin can be irritating to the skin and emit harmful fumes.

Should you wear a mask during 3D printing?

Wearing a mask during the use of a 3D printer can be a useful precautionary measure, especially in certain situations. Here are some considerations:

- Material Type Used: Using materials like ABS, which can emit more harmful fumes, might justify wearing a mask. For less emissive materials like PLA or PETG, the risk is lower, but some caution is still advised.

- Ventilation and Workspace: If you are working in a poorly ventilated space, wearing a mask can help reduce the inhalation of potentially harmful particles and vapors. Good ventilation is crucial during 3D printing.

- Exposure Duration: If you spend long hours near the operating printer, a mask can offer additional protection against prolonged exposures to emissions.

- Personal Sensitivity: If you are particularly sensitive to smells or have pre-existing respiratory conditions, wearing a mask can be an important safety measure.

- Mask Type: For a mask to be effective against ultrafine particles and chemical vapors, it must be specifically designed for this use. Ordinary surgical masks will not be effective against chemical vapors.

Can you sleep while 3D printing?

It is not recommended to sleep while 3D printing, mainly for two major reasons: potentially dangerous emissions and the risk of fire.

Emissions: Even if you use materials considered safer, such as PLA, 3D printers can emit ultrafine particles and volatile organic compounds when they heat the filaments. These emissions can affect indoor air quality, and prolonged exposure during sleep can increase health risks, especially for the respiratory tract.

Fire Risk: Although 3D printers are generally designed to be safe, there is always a risk of technical failure that could lead to a fire. This could be due to various factors, such as a short circuit, overheating, or hardware malfunction. While a smart smoke detectors can provide an alert in case of fire, it is better to prevent the situation by avoiding leaving a 3D printer operating unattended.

What is the best way to eliminate or reduce fumes when 3D printing with PLA?

To reduce or eliminate fumes and emissions when 3D printing with PLA, you can follow several best practices:

Use of a Filtration System: Installing an air filtration system, like AlveoONE or another HEPA filter with an activated carbon filter, can greatly reduce particles and vapors in the air. These systems are designed to capture ultrafine particles and VOCs released during printing.

Improving Ventilation: Ensure your printing space is well ventilated. Opening windows or using a ventilation system can help disperse emissions and improve air quality.

Extruder Temperature Control: PLA generally does not require as high an extrusion temperature as other materials. Printing at the lowest possible temperature (while ensuring good print quality) can reduce emissions.

Regular Printer Maintenance: Regular maintenance of the printer can help prevent overheating and excessive emissions. This includes checking the condition of heating elements, nozzles, and electronic components.

Quality PLA Choice: Use good quality PLA. Lower quality filaments may contain additives or impurities that increase emissions during printing.

Using a Printer Enclosure: Using an enclosure like Printercase can help contain emissions. Some enclosures are equipped with integrated filters to purify the air inside the enclosure.

Monitor the Printer: Be attentive to any unusual changes in emissions or odors during printing. If you notice an increase in fumes or odors, stop the printing and check the printer to identify the cause.

Can a closed 3D printer be used safely in a small house with a baby nearby?

No, it is not recommended to use a closed 3D printer in a small house with a baby nearby, even with all possible precautions. Scientific advice has concluded that children under 9 years old are particularly vulnerable to emissions generated.

The emitted particles cause moderate toxicity at the level of human lung cells, and this risk is amplified in children. Babies are particularly sensitive to emissions of ultrafine particles and volatile organic compounds (VOCs) that can be emitted by 3D printers, even those that are closed.