The main purpose of a 3D printer housing is to contain and filter the toxic emissions produced by 3D printing. And so, thanks to a filtration system. In the absence of being able or willing to create a completely airtight enclosure, it is important to use a filtration system that will expel the air from the enclosure to the outside.

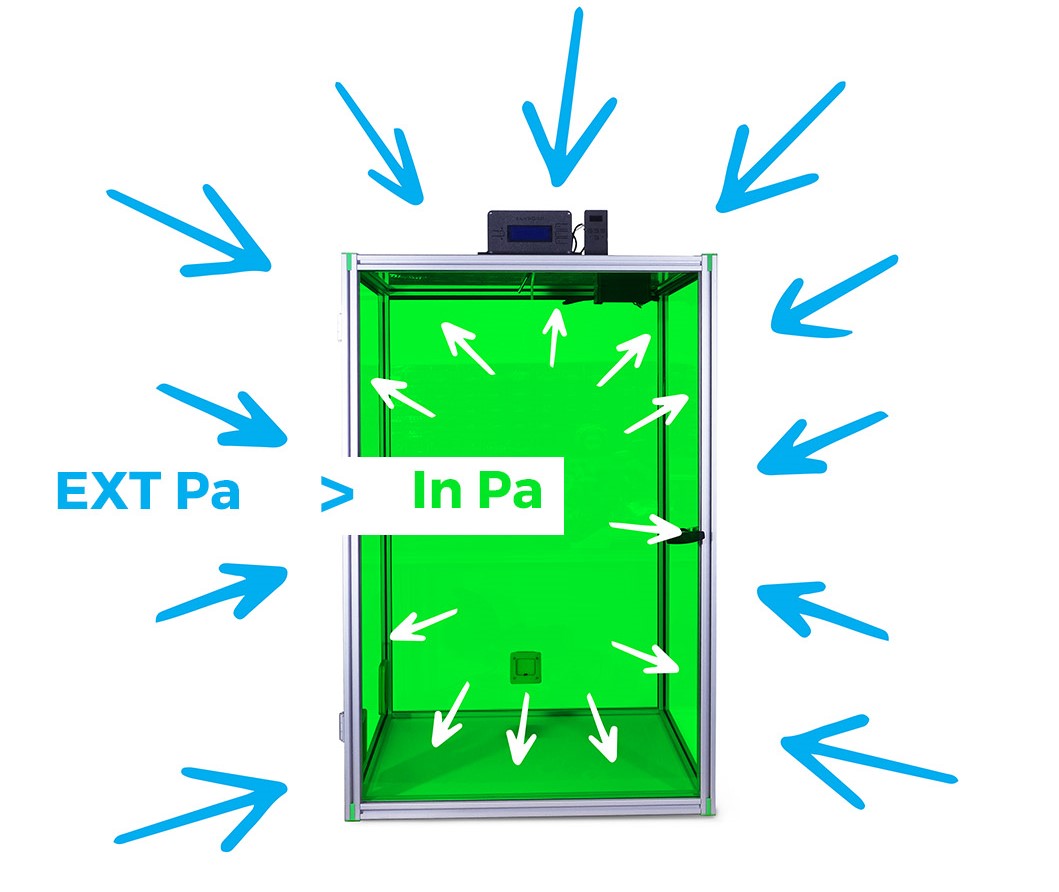

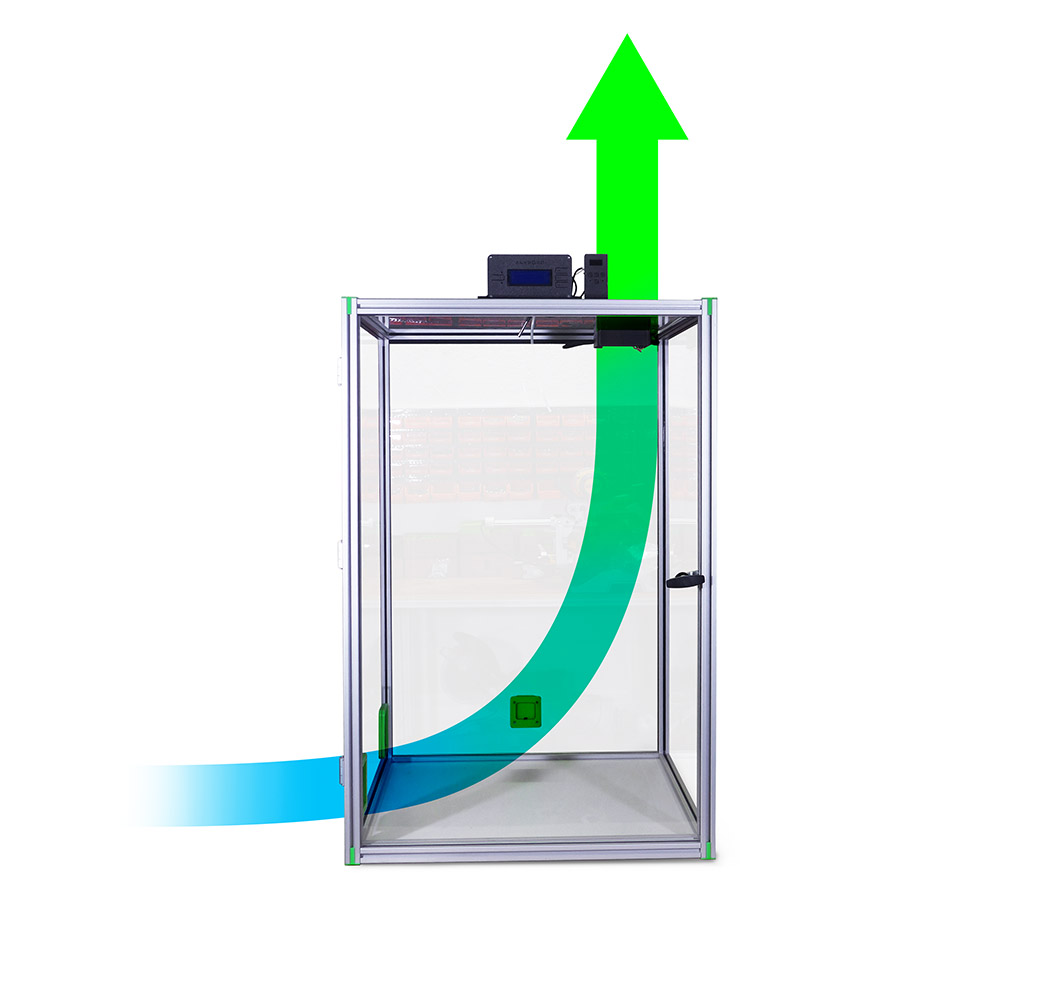

To achieve this, an airflow needs to be created. The incoming airflow into the enclosure must be inferior to the one being expelled, in order to create a slight depression inside the enclosure

This depression is crucial as it ensures that the polluted air inside the enclosure cannot escape. To compensate for the outflow, which is greater than the inflow, ambient air will enter through all the interstices, spaces, and holes in the enclosure. Air will only leave through the filtration system.

II. The test protocol

Enclosure conception

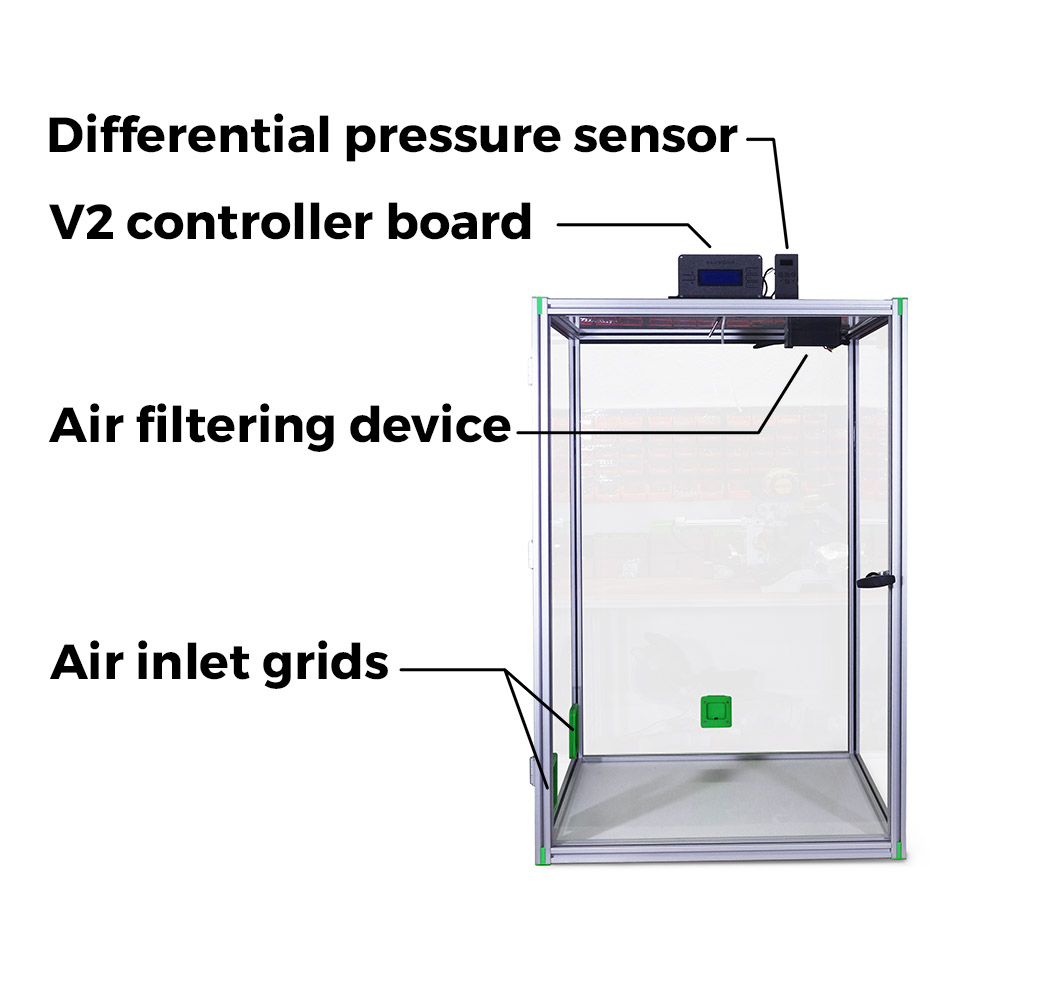

At Alveo3D, we design enclosures with well-defined air inlets, to ensure that the AlveoONE filtration system creates a depression in the enclosure.

As the enclosures are not airtight, we try to minimize gaps and other small spaces. To ensure good airflow through the enclosure, you must apply the rule of the “opposite side”. For example, if the filtration system is placed on the upper part, the air inlets should be located on the lower parts of the enclosure. It’s important to distribute these air inlets evenly, with a total surface area equivalent to 75% of the filter surface. However, it is essential not to place them directly in line with the surface of the heating plate to avoid warping.

The filtration system

Most filtration systems consist of a fan and a filter. With the AlveoONE filtration system, we combine an ALHP-H8 high-pressure fan with a P3D filter.

A high air flow rate is not necessarily required, but high pressure is imperative to push the air through the P3D filter media. A simple PC fan would not be able to provide the pressure needed to ventilate the air volume of a 3D printer enclosure in a reasonable time.

Measuring device

We carried out a test protocol to measure the differential pressure between the inside and outside of the enclosure. To do this, we used a tool of our design equipped with a Sensirion sensor (SDP 810). It is accurate to approximately 0.125 Pa.

This tool enables a real-time comparison of the pressure inside and outside the enclosure to better understand the impact of air inlets and filtration speed on enclosure pressure.

TEST 1 :

In our first test, we measured the pressure in our enclosure by varying the filtration speed with the air inlet grids open to 100%.

TEST 2 :

For the second test, we maintained a filtration speed of 100% while varying the opening of the air inlet grids.

The various test series

Our tests were carried out on a custom-made 3D printer enclosure with calibrated air inlet grids, an AlveoONE filtration system, and a P3D filter. We also installed a V2 control board on the enclosure to manage fan speed and, therefore, airflow during our various tests.

Test 1 : Pressure changes with the filtration speed and the air inlet grids open to 100%

III. Results: air pressure differences in a 3D printer enclosure

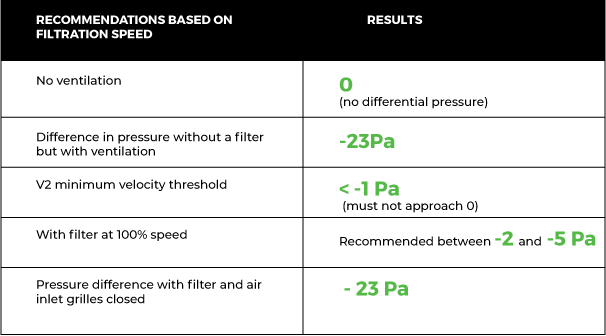

If there is no ventilation, there is no pressure difference in the enclosure. If ventilation is on, it is important that the pressure range remains between 2 and 5 Pa for a maximum volume of 1 m³.

It is also important that the pressure difference does not fall below 1 Pa, as the device used has an accuracy of 0.125. It is therefore advisable to maintain an adequate minimum pressure to ensure the reliability of the measurements taken.

Depending on the airtightness and opening of the grids, we can say that the minimum ventilation limit is 40%, here with the grids fully open and the airtightness of our enclosure.

Therefore, we can see that the aim is to have a negative pressure of -2 to -5 Pa lower on average in the enclosure. It’s not necessary to have lower pressure, as the fan could be forced for no reason. There are two levers for varying the pressure in the enclosure:

- Fan speed

- Air inlet surface

IV. Recommendations for managing pressure in a 3D printer enclosure

We have 2 recommendations for controlling the air pressure in a 3D printer enclosure:

- Recommendation n°1: Control of ventilation speed

With the use of a V2 control card dedicated to the control of our filtration systems. It allows setting and controlling the fan speed. Adjusting the speed enables the operator to control the pressure in the enclosure, and to filter its volume more or less rapidly.

Recommendation n° 2: Air inlet grids

Test 2 : Pressure changes with the variation of the opening air inlet grids

Calibrated air inlet grids provide the ideal surface for the AlveoONE filtration system with a PrinterCase enclosure. They distribute the airflow at two points of entry to the enclosure to prevent warping.

In the case of a DIY housing, the version with sliding doors allows you to adjust the surface area of the air inlets to suit the airtightness of your enclosure. This allows you to manage incoming airflow and ensure a constant negative pressure in your housing.

Ideal positioning is on opposite panels, with the filter and grids facing each other. The distance between the grids on the panel corresponds at least to the width of the printing plate. This configuration favors airflow to avoid the risk of warping.

The air inlet surface is perfectly optimized for all housings up to 1 m3 with the AlveoONE air filtration system. Total airtightness of the box is not necessary, but it is advisable to keep interstices to a minimum.

V. Conclusions on air pressure in a 3D printer enclosure

It’s important to ensure a pressure difference between the inside and outside of the enclosure to guarantee effective filtration. Our systems work together:

- AlveoONE

- V2

- Grids

This ensures the best filtration performance. More than having a good filtration system; you need global protection.

FAQ

Does a 3D Printer Need Ventilation?

How can ventilation systems impact print quality in 3D printing?

The role of ventilation into a 3D printer enclosure is essential for several reasons:

- Heat Management: 3D printers, especially when operating at high temperatures for materials like ABS, generate significant heat. An enclosure helps in maintaining a consistent temperature but also needs to vent excess heat to prevent overheating of the printer components and the printed object.

- Fume Extraction: Printing materials emit VOCs and UFPs. Ventilation systems or air filters integrated into enclosures can extract these fumes from the enclosed space, thereby reducing the user’s exposure to potentially harmful emissions.

- Humidity Control: Enclosures can trap humidity, which can affect print quality and filament properties. Ventilation helps in controlling humidity levels within the enclosure.

- Air Quality: Continuous extraction of air from the enclosure and replacement with fresh air helps maintain the air quality, not just within the enclosure but also in the surrounding environment. This is particularly important in shared or poorly ventilated spaces.

0 Comments