Dental CAD/CAM, short for Computer Aided Design and Manufacturing, represents a major advance in the field of dentistry. This revolutionary technology has transformed the way dental prostheses are designed and manufactured, offering numerous benefits to dentists and patients alike. According to Vantage Market Research, the dental 3D printing market is expected to reach $14.6 billion by 2032, with exponential growth forecast at 18.4% over the next eight years.

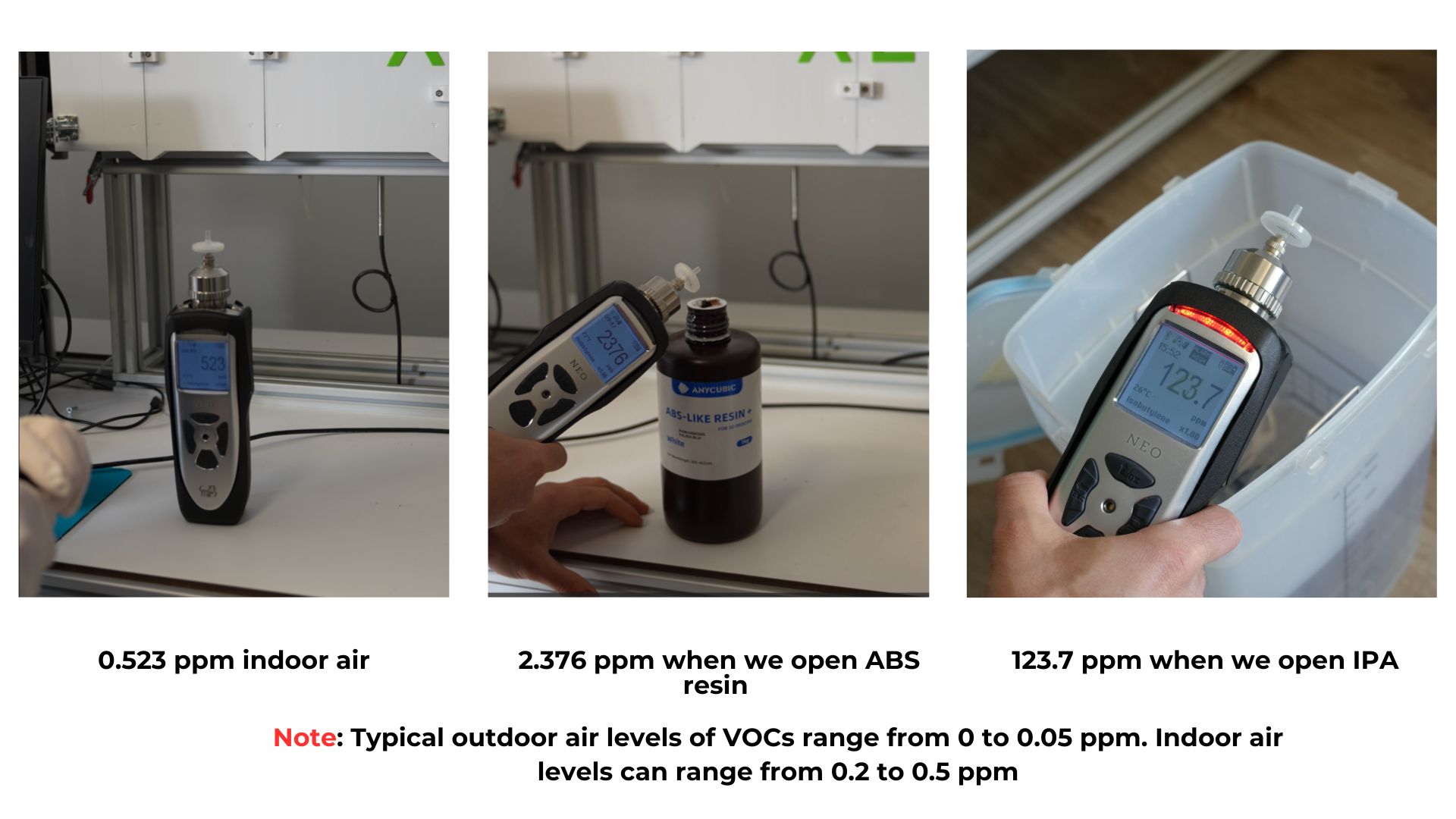

However, the use of resins and solvents in this process raises a significant public health issue: the emission of volatile organic compounds (VOCs)

I. How it works

The dental CAD/CAM process involves the use of specialized software and machines to create customized dental prostheses in three main stages:

- Scanning: The patient’s mouth is first scanned using an intra-oral scanner, generating a precise digital image of his or her dentition and soft tissues.

- Design: CAD (Computer-Aided Design) software is used to create a virtual 3D model of the dental prosthesis from the scanned data. The dentist or dental technician can then adjust and refine the design according to the patient’s specific needs.

- Manufacturing: The 3D model is then sent to a CAM (Computer Aided Manufacturing) machine, which uses various techniques, such as machining, milling or 3D printing, to manufacture the dental prosthesis from biocompatible materials such as zirconia, ceramic or resin.

Photo credit: Formlabs

II. What are VOCs and where do they come from in dental 3D printing?

VOCs are organic chemical substances that evaporate easily at room temperature, transforming into gases or vapors. In the context of dental 3D printing, VOCs come from two main sources:

- Resins: The light-sensitive resins used to print dental prostheses often contain VOCs such as acrylic monomers and solvents. These VOCs are released into the air during printing and during the post-treatment process, which includes cleaning and curing the dentures.

- Solvents : Isopropyl alcohol (IPA) is commonly used to clean uncured resins and printed surfaces. IPA is itself a significant VOC and contributes to overall VOC emissions in the working environment.

III. Types of resins used in CAD/CAM

Various types of resin are used in dental CAD/CAM, each with its own specific properties and applications.

1. Acrylic resins

- Most widely used in dental 3D printing

- Versatile: manufacture of crowns, bridges, prostheses, splints, surgical guides, etc

- Good mechanical properties: strength, durability

- Wide choice of colors and translucency

- Affordable price

- Disadvantages: VOC emissions during printing and post-processing.

Risk of allergies and sensitization.

2. Biocompatible resins

- Designed for direct contact with soft tissues.

- Used for partial dentures, inlays/onlays, splints, etc.

- High biocompatibility: minimizes the risk of allergic or inflammatory reactions.

- Mechanical properties vary according to composition.

3. Biodegradable resins

- Degradable in the environment over time.

- Used for temporary applications : trial models, resorbable surgical guides.

- Reduce environmental impact.

4. Molding resins

- Liquid or pasty, used to create physical molds.

- Used to manufacture removable dental prostheses, splints, etc.

- Good detail reproduction.

- Variety of materials: plaster, polyurethane, silicone, etc.

- Some molding resins may release unpleasant odors or VOCs.

Photo credit: Sprintray

The fact that resins don’t smell doesn’t mean they are not risky. It makes users ignore the risk of chemical exposure. Many manufacturers tend to reduce the smell of resin. It is very important to educate employers, employees, and CEOs about the risks confirmed by scientific data.

IV. How can VOCs affect your health?

Exposure to VOCs, particularly in enclosed, poorly-ventilated spaces, can lead to adverse short- and long-term health effects. Risks include :

- Respiratory tract irritation: VOCs can irritate the eyes, nose, throat and lungs, causing symptoms such as coughing, sneezing, runny nose and sore throat.

- Allergies and sensitization: Repeated exposure to certain VOCs can sensitize individuals, triggering allergic reactions such as asthma or dermatitis.

- Neurological effects: Studies have linked exposure to high levels of VOCs to neurological disorders such as headaches, dizziness, fatigue and impaired concentration.

- Carcinogenicity: Some VOCs, such as benzene and formaldehyde, are classified as carcinogens by the International Agency for Research on Cancer (IARC). Prolonged exposure to these VOCs may increase the risk of developing certain cancers.

V. Studies on the risks of VOCs in dental 3D printing

INRS (The French National Research and Safety Institute for the Prevention of Occupational Accidents and Diseases) reports on a study of volatile organic compound (VOC) emissions during 3D printing using various plastics and UV resin in photo-polymerization processes. The study revealed high concentrations of acrylates from UV resins and aldehydes from plastics, highlighting the need for printers equipped with enclosures and extraction systems to reduce user exposure to these emissions.

Emissions of volatile organic compounds (VOCs) in 3D printing, Source: INRS

VI. Our solutions

Alveo3D offers a complete range of air filtration solutions specifically designed to meet the unique needs of dental 3D printing.

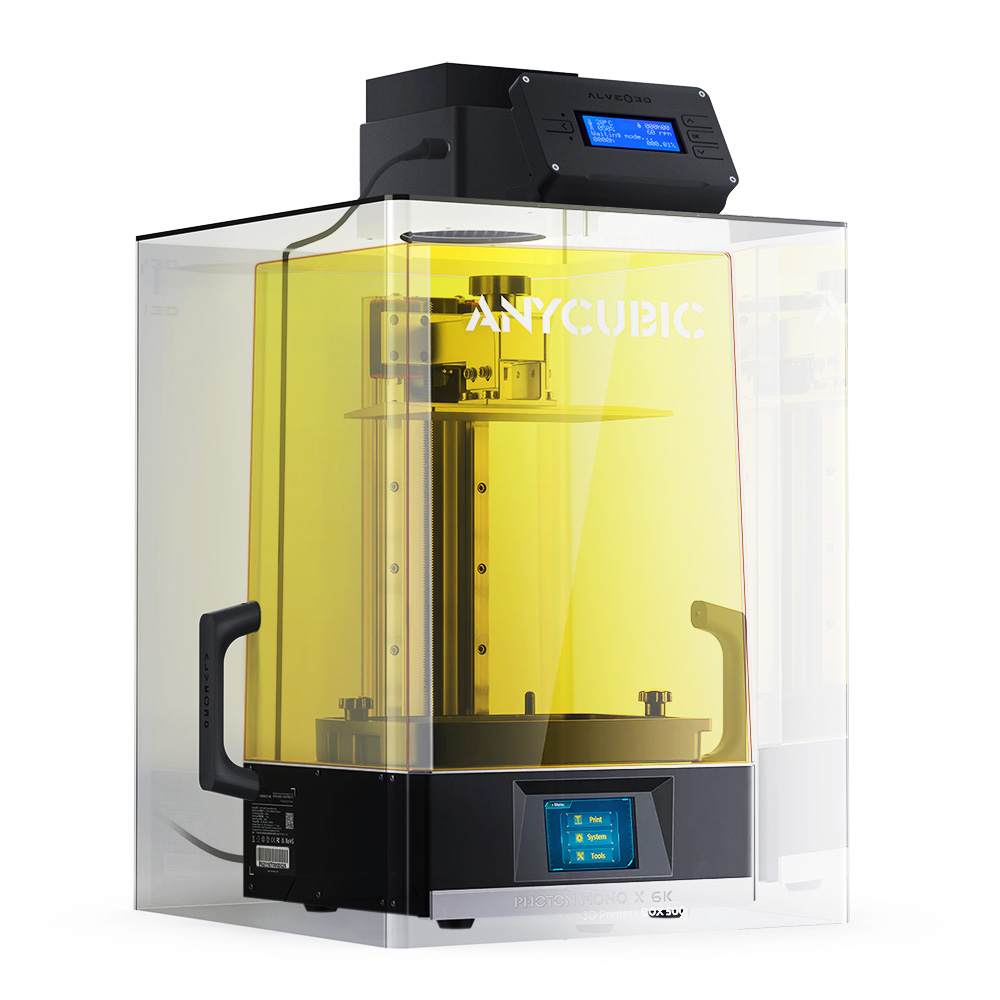

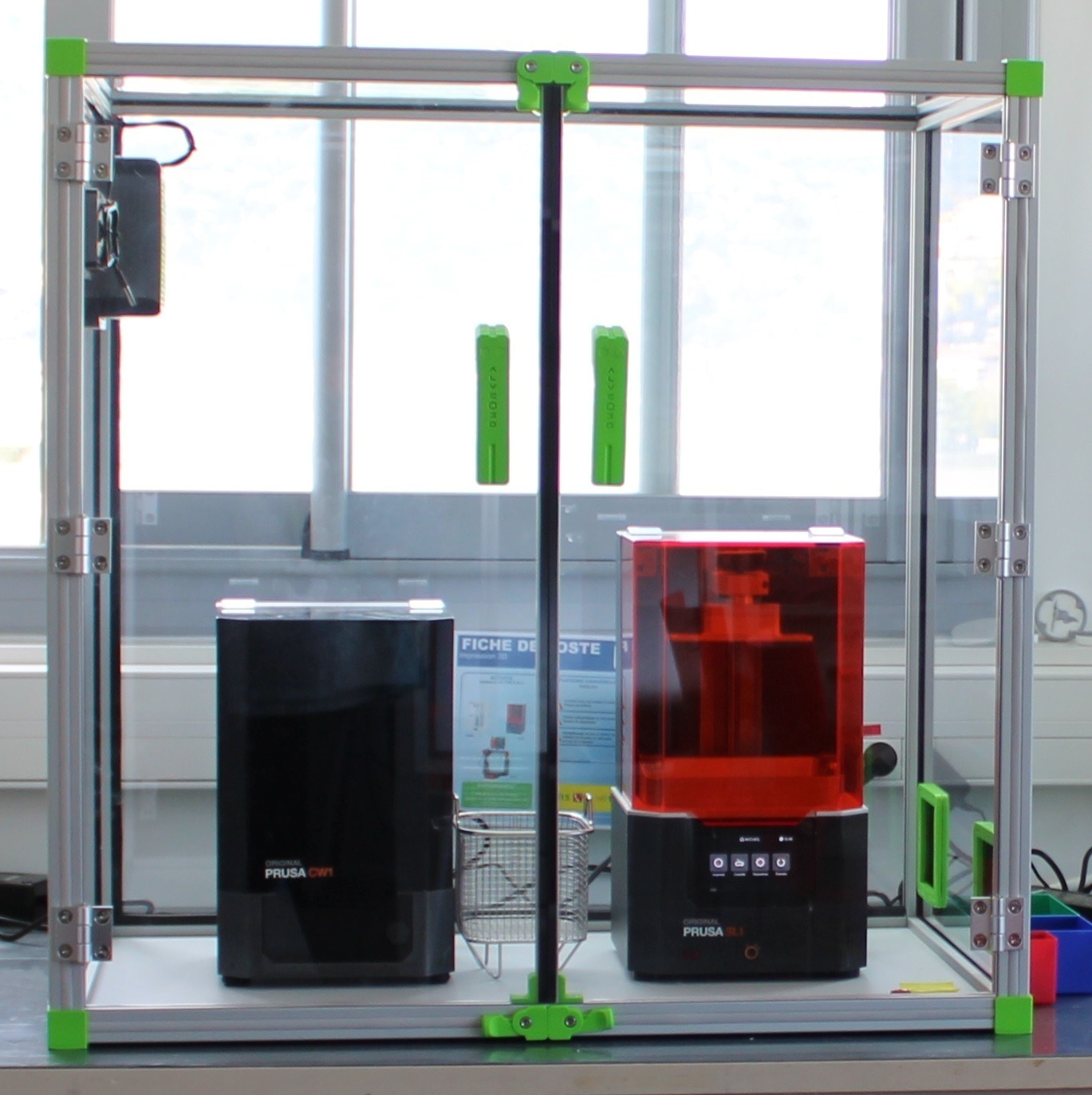

- Resin 3D printer housings: These systems enable targeted capture of pollutants directly at source, close to the 3D printer. They are ideal for small workspaces or for capturing emissions from multiple printers.

- M100 filter Alveo3D’s activated carbon filters are specially designed to effectively capture VOCs and other gaseous pollutants present in ambient air. They offer optimum protection against the health risks associated with VOC exposure.

- P3DL filter: Alveo3D HEPA filters effectively capture airborne particles, including fine dust, bacteria and viruses. They help maintain a clean and healthy working environment.

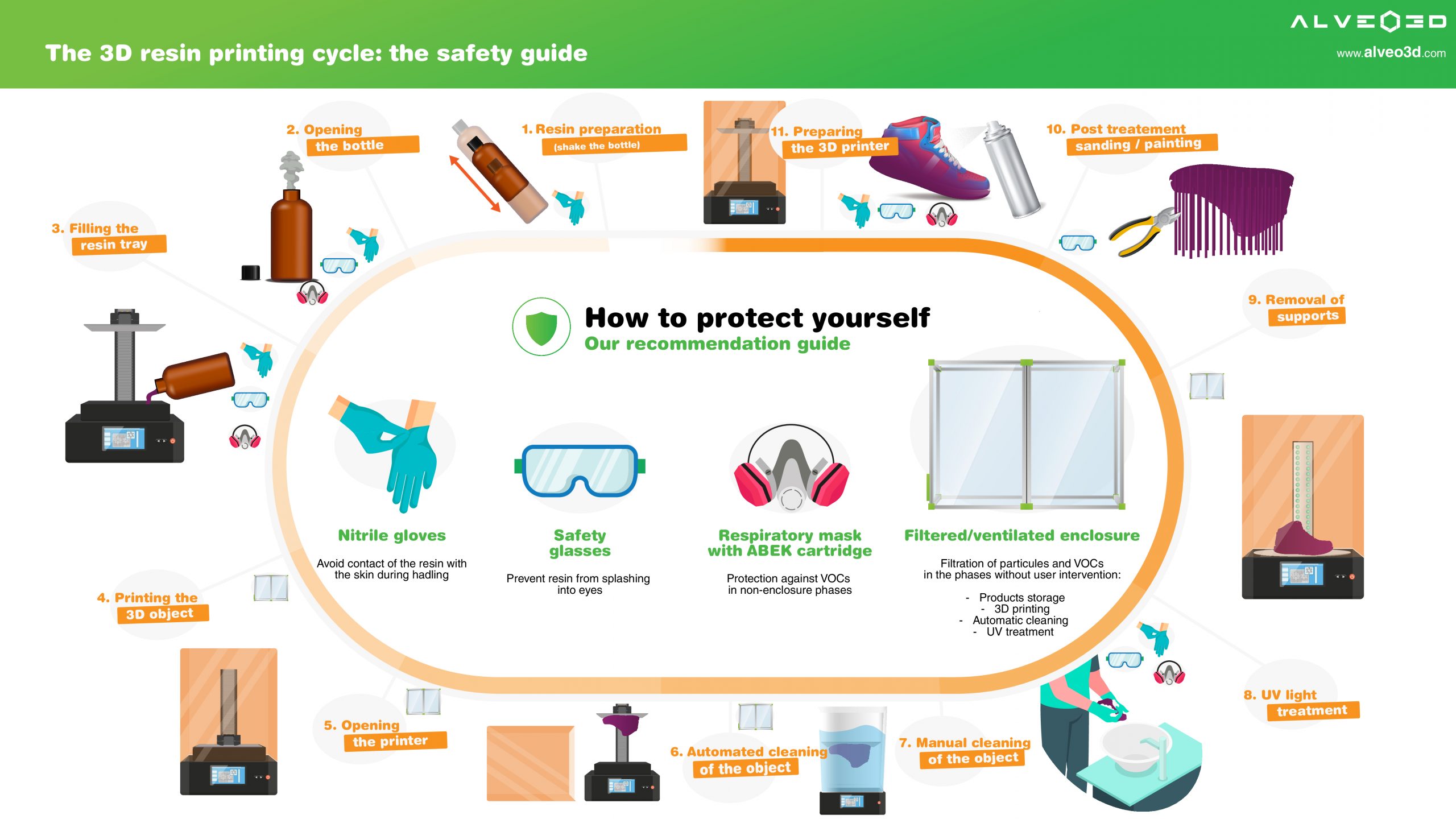

VII. 3D resin printing safety guide

Here are some measures to minimize VOC exposure during resin printing:

✅ PPE: wear gloves, a mask with appropriate VOC filtration and safety glasses when handling resin and cleaning prints.

✅ Resin selection: consider using low-VOC or biocompatible resins where available.*

✅ Cleaning methods: Explore alternative cleaning methods such as water-based solutions or closed cleaning stations to minimize IPA exposure.