I. What are VOCs?

VOC is the acronym for “Volatile Organic Compound”. VOC has very low boiling points and are easily released as vapor or gas from products containing them. The origin of this substance can be artificial or natural. Some are known to be harmless to health, the rest are toxic to humans.

Some common VOC compounds include formaldehyde, benzene, styrene, acetone… and they are produced from many consumer products such as cigarettes, glue, paints, dry cleaning liquids, wood preservatives, and printer resin. Cleaning and disinfecting equipment, air fresheners, construction materials, printers, photocopiers, pesticides, etc. VOCs are present everywhere around us, including household objects.

Source: Internet

II. VOCs in 3D printing

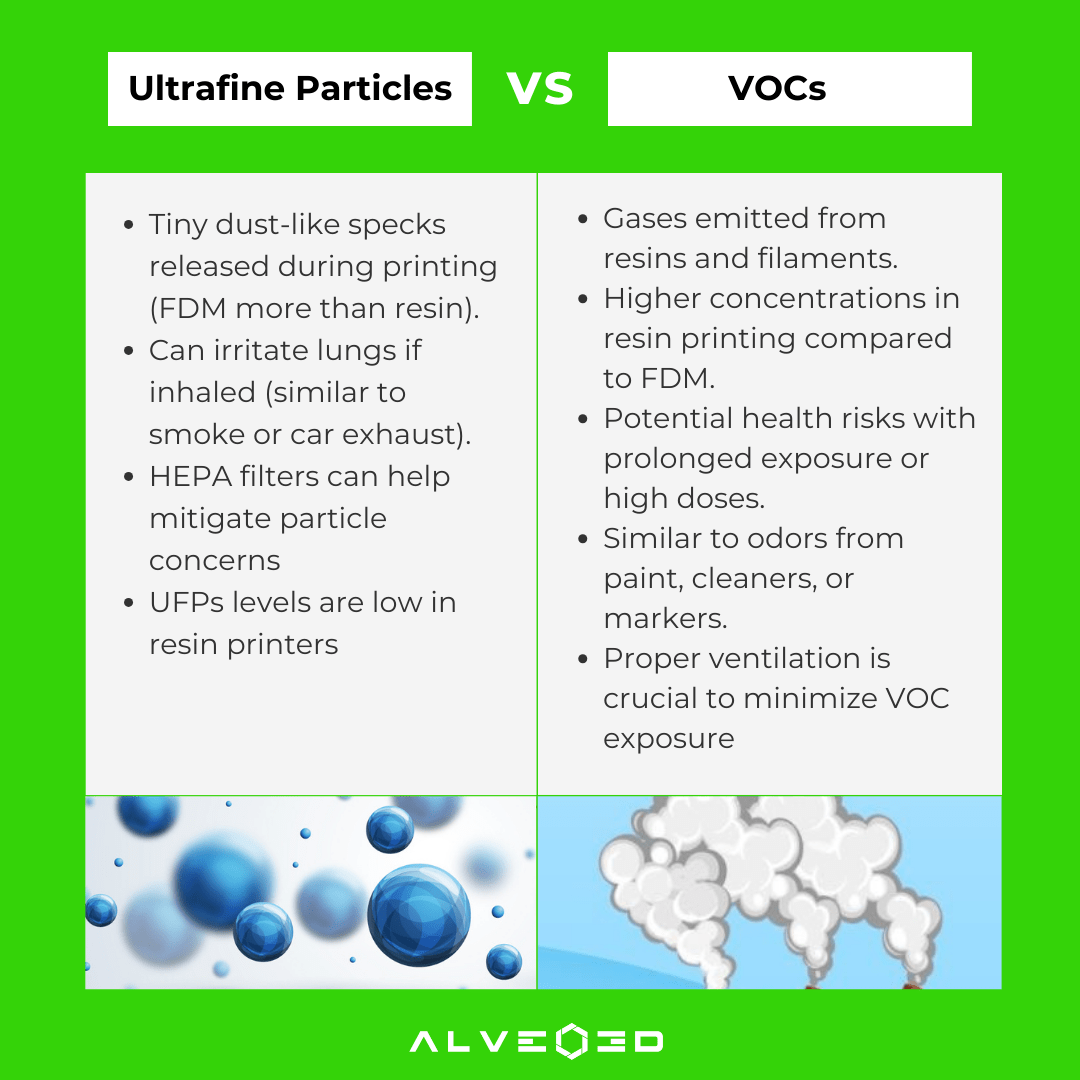

In fact, when it comes to emissions in 3D printing, we are mainly discussing micro particles in FDM and VOCs release in 3d printing resin SLA. These compounds are emitted from materials used in 3D printers, especially when printing with certain types of filaments (ABS) or resins.

For SLA, VOCs in 3D printing refer to the gases and vapors emitted pre-printing (material preparation), during the printing process, and post-printing (cleaning). They can pose health risks to individuals exposed to them, including the makers and those in proximity, all of whom can be affected by the release of VOCs.

The comparison between ultrafine particles (UFPs) and volatile organic compounds (VOCs)

Here’s a closer look at how VOCs get involved in 3D printing:

1. FDM printing and VOC emissions

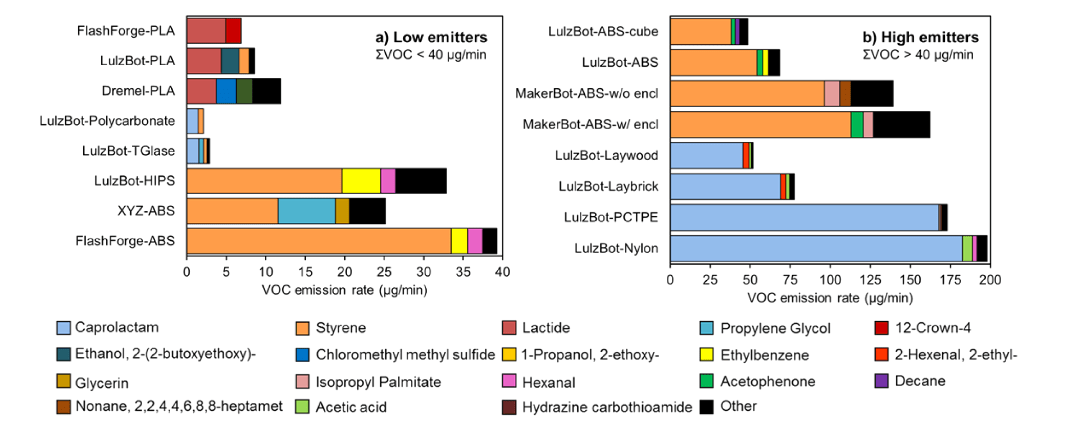

Volatile organic compounds (VOCs) emissions from Fused Deposition Modeling (FDM) 3D printers are a concern due to the potential health risks when these compounds are inhaled. Studies have shown that different types of filament materials used in FDM printing, like ABS and PLA, release different amounts of VOCs during the printing process. The process of heating these plastic materials to create the 3D printed objects leads to the release of VOCs.

Source: Environmental Science & Technology

ABS filaments, in particular, have been noted to release a greater number of VOCs compared to PLA filaments. This suggests that users of ABS may be exposed to higher volumes of potentially hazardous emissions. Some of the VOCs identified in the emissions include styrene, which is known to be released from ABS, and lactide, which comes from PLA. Other filament types like ASA and nylon may also release VOCs

VOCs in 3d printing FDM

2. SLA printing and VOC emissions

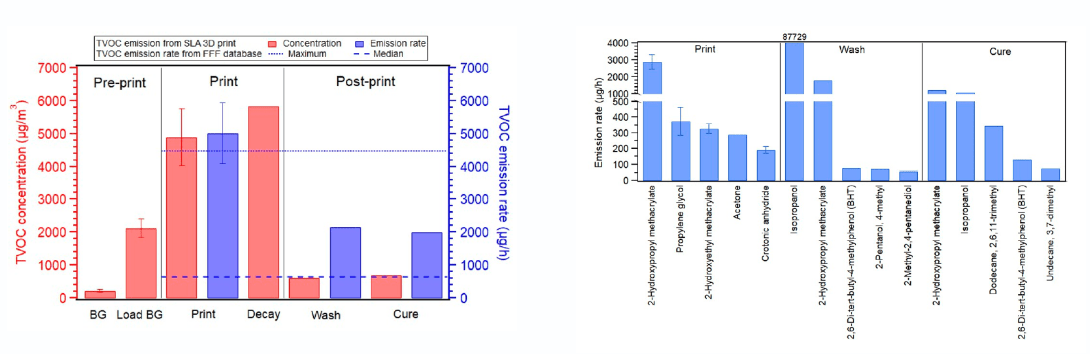

SLA printing releases significantly more VOCs compared to FDM printing. In fact, VOC emissions from SLA printing can be 3 to 6 times higher.

The study was published in 2022 by the American Chemical Society. They identified and quantified a comprehensive list of emitted VOCs using an established analytical laboratory that includes a database specific to indoor environments. Here are some key findings of the study:

- 🔍 High VOC release, low particle: The study observed minimal emissions of particles but identified 30 to over 100 individual VOCs emitted across different phases of the SLA 3D printing process, including printing, washing, and curing. Total VOC emissions were notably higher than those from material extrusion 3D printing, with major VOCs linked to the resin and chemicals used in these processes.

- 🛠️ Variety of emitted chemicals: A complex mixture of sensitizers, carcinogens, irritants, and flammable chemicals, including esters, alcohols, aldehydes, ketones, aromatics, and hydrocarbons, were identified as emissions from the SLA processes. These emissions may pose a hazard to indoor air quality and human health, especially in non-industrial environments where 3D printers are commonly used.

- 🚨 Health Risks from Exposure: The emitted VOCs, including known irritants and carcinogens like formaldehyde and naphthalene, could exceed recommended indoor levels, potentially causing irritation and other health impacts to users.

VOC (Volatile Organic Compound) emissions during different stages of the SLA 3D printing process. Source: ACS Chem. Health Saf

- Pre-Print Stage: Before printing begins, the background VOC concentration is relatively low, with the bar chart showing a level just above 1000 µg/m³.

- Print Stage: During printing, VOC concentration and emission rates escalate sharply. The concentration peaks well above 6000 µg/m³, significantly higher than the pre-printing levels. Similarly, the emission rate during printing also rises, exceeding the background rate noticeably but does not peak as high as the concentration.

- Post-Print Stage: After printing, during the ‘Decay’ phase, both concentration and emission rates decline, but they remain higher than background levels. The ‘Wash’ phase sees a slight increase in emission rates again, indicated by a rise in the blue bars. During the ‘Cure’ phase, concentration and emission rates drop off, with emission rates approaching the background levels.

- Specific VOC Emissions: The second chart lists specific VOCs emitted during the ‘Print’, ‘Wash’, and ‘Cure’ stages. Here, isopropanol has a notable spike in emissions during the ‘Wash’ phase, reaching an emission rate of over 800 µg/h.

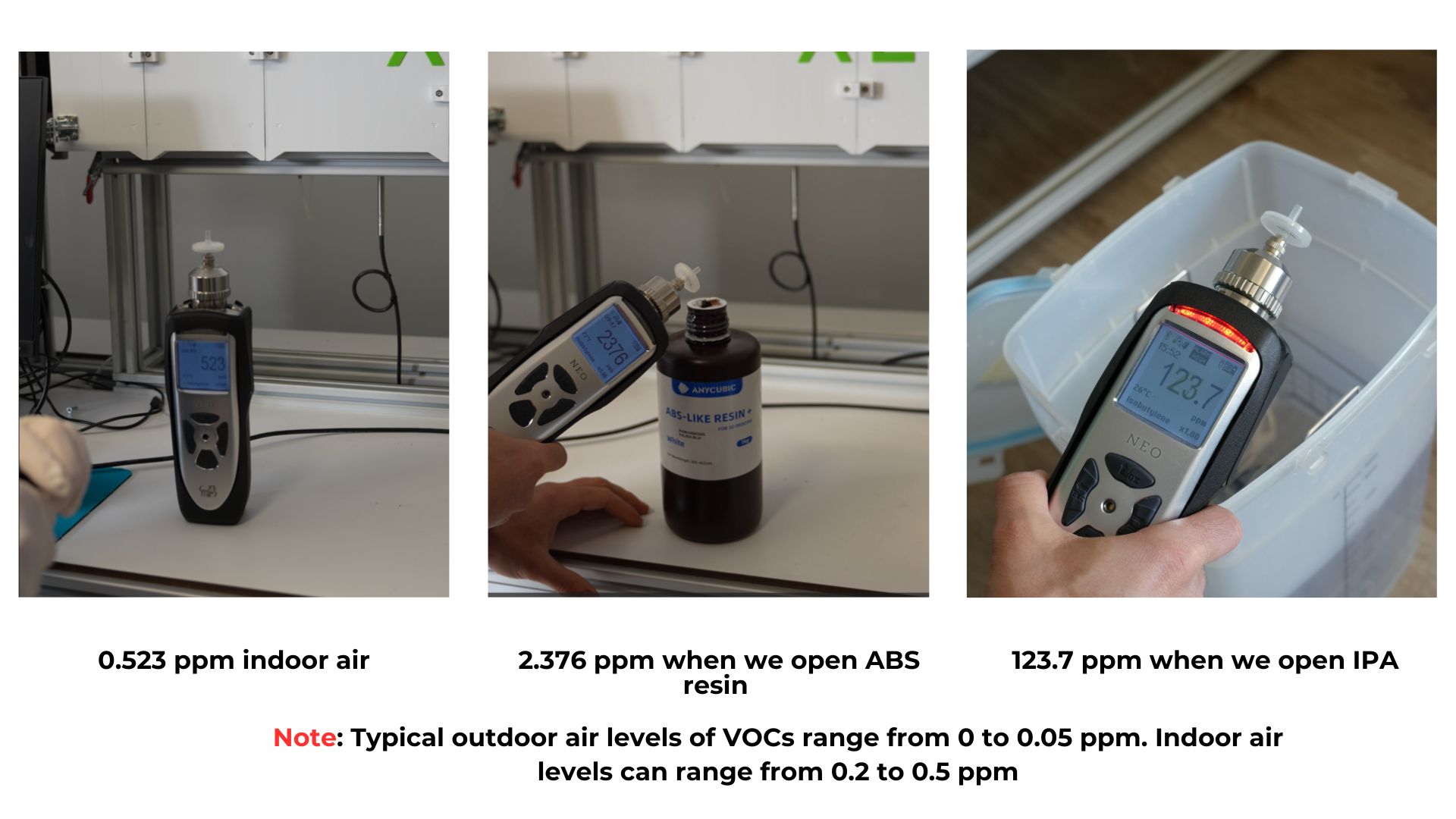

Our small test shows that 3D printing resins emit higher levels of VOCs when we simply open them

III. Dental laboratories, and medical equipment manufacturers ⚠️

One of the primary sectors extensively utilizing SLA methods is medical equipment manufacturing. These manufacturers employ SLA 3D printing to create a variety of medical equipment, including surgical instruments, dental implants, and medical models, etc

SLA technology enables the rapid production of detailed and specific medical and dental parts. It is especially useful for custom dental work in clinics and laboratories, as well as creating economically viable medical devices.

However, Medical device manufacturers should absolutely be more concerned about VOCs emitted during the 3D printing process. Workers involved in the 3D printing and post-processing stages are at higher risk of VOC exposure if proper ventilation isn’t implemented ⚠️

Source: Formlabs

IV. How harmful are VOCs to human health?

VOCs are present in the air, particularly indoors. Certain substances pose no risk to humans, while excessive exposure to others can result in respiratory issues as well as issues with the eyes, nose, and throat. Severe cases may cause harm to the kidneys, liver, and central nervous system, among other organs.

When exposed to large amounts of VOCs over an extended period of time, substantial levels of cancer have even been found to occur. Children and those who have asthma are more vulnerable to this compound’s negative effects. VOCs impact the respiratory system and lungs, leading to muscle weakness, according to a paper published by the American Lung Association.

VOCs found in 3D printing resin and potential negative effects

| VOC Type | Negative Effects |

|---|---|

| Acrylates (very high concentration) | Skin irritation, respiratory irritation, allergic skin reaction |

| Methacrylates | Similar to acrylates, can also be neurotoxic |

| Formaldehyde | Eye, nose, and throat irritation, potential carcinogen |

| Toluene | Dizziness, headaches, nausea, potential reproductive problems |

| Xylene | Similar to Toluene, also a skin irritant |

| Aromatic Hydrocarbons | Respiratory problems, skin irritation, some may be carcinogenic |

| Isopropyl Alcohol (IPA) | Skin irritation, respiratory irritation, eye irritation, flammability |

| Acetone | Irritate the eyes, nose, and throat. In high concentrations, it can cause headaches, dizziness, and nausea. Long-term exposure may pose additional health risks. |

| Styrene | Irritation of eyes, nose, and throat, headaches, dizziness, nausea, difficulty concentrating, potential long-term health effects like cancer (according to IARC) |

📝 Note:

- This table lists some of the most common VOCs found in 3D printing resins. The specific VOCs present may vary depending on the brand and resin formulation.

- IARC (International Agency for Research on Cancer) is part of the World Health Organization (WHO)

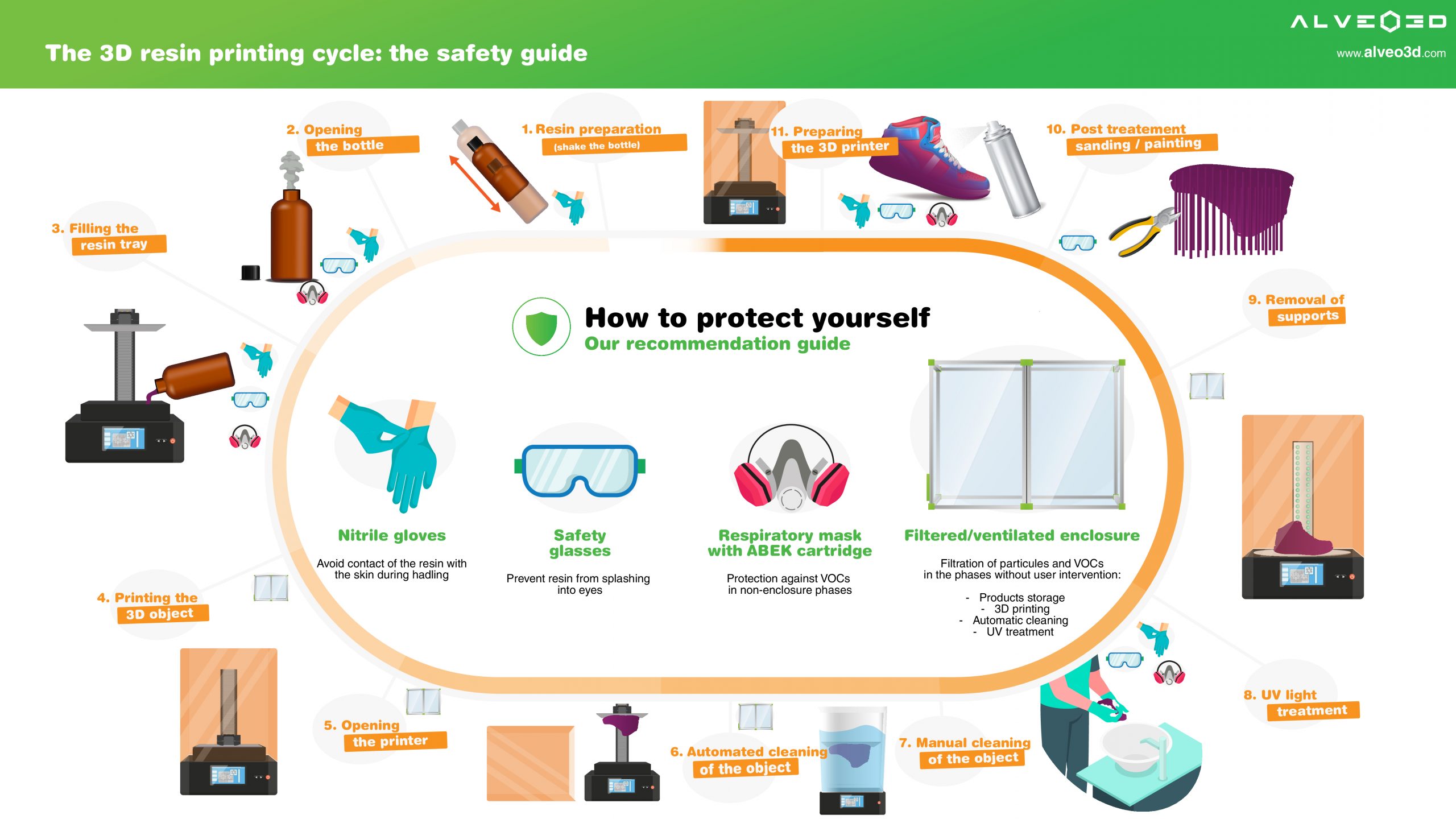

V. Reduce the risks

To reduce the risks associated with volatile organic compounds (VOCs) emissions from (SLA) printing in environments such as dental clinics, dental laboratories, and medical equipment manufacturing facilities, consider implementing the following solutions:

✅ PrintBox SLA Enclosure: Offered by Alveo3D, this enclosure is specifically designed to contain SLA printers, effectively reducing the spread of VOCs into the workspace. It’s a targeted solution for maintaining air quality during the printing process.

With 50mm thick layer of activated carbon can treat better absorption of VOCs). To discover all our solution for resin 3d printing safety, you can read fully our article 👉 :The best solution for resin 3d printing safety

✅ Well-ventilated workspace: Ensure that the area where SLA printing takes place is well-ventilated. This helps in diluting and removing airborne contaminants, including VOCs, thereby reducing potential exposure.

✅ Proper curing and post-processing areas: Designate specific areas for curing and post-processing of printed items. These areas should be equipped with additional ventilation or air purification systems to handle the off-gassing efficiently.

✅ Regular air quality checks: Implement a routine for regular monitoring of air quality within the facility to ensure that VOC levels remain within safe limits.

✅ Use of protective equipment: When handling uncured resins or during the post-processing of printed parts, staff should use appropriate personal protective equipment (PPE), such as gloves, masks, and goggles.

By adopting these measures, facilities utilizing SLA technology can significantly mitigate the health risks associated with VOC emissions, ensuring a safer working environment for everyone involved.

VI. Alveo3D’s opinion

In fact, the manufacturers aim to produce resin and filament without any odor, but this might make people less careful. The transparency about VOC toxicity levels and their effects is crucial for safe 3D printing. The safety of 3D printing, especially regarding emissions and materials, deserves more open discussion.

3D printer manufacturers should inform buyers upfront about potential dangers:

- Product manuals: Go beyond basic warnings. Include detailed information on potential hazards associated with VOC emissions, fumes, and nanoparticles.

- Ventilation recommendations: Companies could advise on proper ventilation setups for different printer types.

- Focus on safer materials: Investing in research and development of low-emission filaments and resins would benefit everyone

- Highly efficient filter: Look for filters with certifications or test results from independent labs.

References

- Zhang, Q., Davis, A. Y., & Black, M. S. (2022). Emissions and Chemical Exposure Potentials from Stereo lithography Vat Polymerization 3D Printing and Post-processing Units. ACS Chemical Health & Safety, 29(3), 184–191.

- Azimi, P., Zhao, D., Pouzet, C., Crain, N. E., & Stephens, B. (2016). Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environmental Science & Technology, 50(3), 1260–1268.

VII. FAQ

1. Does the resin itself emit VOCs or not, when I open bottle?

Yes, resin itself emits VOCs even when you open the bottle.

- Resin offgasing: Resin is a liquid mixture that contains VOCs as solvents and other components. These VOCs can escape the liquid state and become airborne even at room temperature, a process called offgasing.

- Opening the bottle: When you open the bottle, you create a larger opening for these VOCs to escape into the surrounding air.

However, there are some factors to consider.

Even if a resin is advertised as “low odor” or “VOC-free,” it’s always best to treat it with caution and follow safe handling practices.

2. VOCs are captured by the liquid resin during the printing process?

No, VOCs are generally not captured by the liquid resin during the 3D printing process. In fact, the printing process itself can often encourage the release of VOCs from the resin. Here’s why:

- Resin as a mixture: Resin is a liquid mixture containing various components, including photopolymerizable monomers (react to form the solid print), solvents, and additives. VOCs are often present in the solvent portion to keep the resin in a liquid state and influence other properties.

- The printing process: During printing, the resin is exposed to light (laser or UV) depending on the technology. This light triggers a reaction in the photopolymerizable monomers, causing them to solidify and form the printed object.

- VOC Release: The light and heat generated during this process can also cause some of the VOCs in the resin to evaporate and become airborne.

3. VOCs emitted during post-printing (cleaning) of 3D printing?

Yes, the cleaning process in 3D printing emit significantly VOCs:

- Cleaning Solvents: Many common cleaning solvents used for 3D printing, such as isopropyl alcohol (IPA), acetone, and methyl ethyl ketone (MEK), are VOCs themselves. These evaporate readily and can release fumes into the air.

- Resin Residue: Uncured or partially cured resin left on the print or in the cleaning container can also emit VOCs as it continues to cure or evaporate.