I. Increase the amount of 3D printing training in schools

3D printing has quickly become a popular technology, loved by many because of its affordability and accessibility. Schools are increasingly using 3D printers to teach a variety of subjects, including science and technology.

In Europe, there are more and more many organizations that offer training in 3D printing. In France, there are more than 1000 people search for 3D printer training each month in Google. These organizations help teachers and students learn how to model in 3D, set up and use the printers, assemble the equipment, choose the right materials, and understand other important concepts.

However, it’s crucial to address the safety concerns associated with 3D printing to protect young learners. It is essential to ensure that 3D printing is done safely to protect both students and staff. This blog series will discuss the importance of increasing 3D printing training in schools, point out the missing point and provide our recommendation to protect future generations.

II. Key safety concerns for young learners

According to the NIOSH guide, there are several potential hazards that need to be managed effectively to ensure a safe learning environment

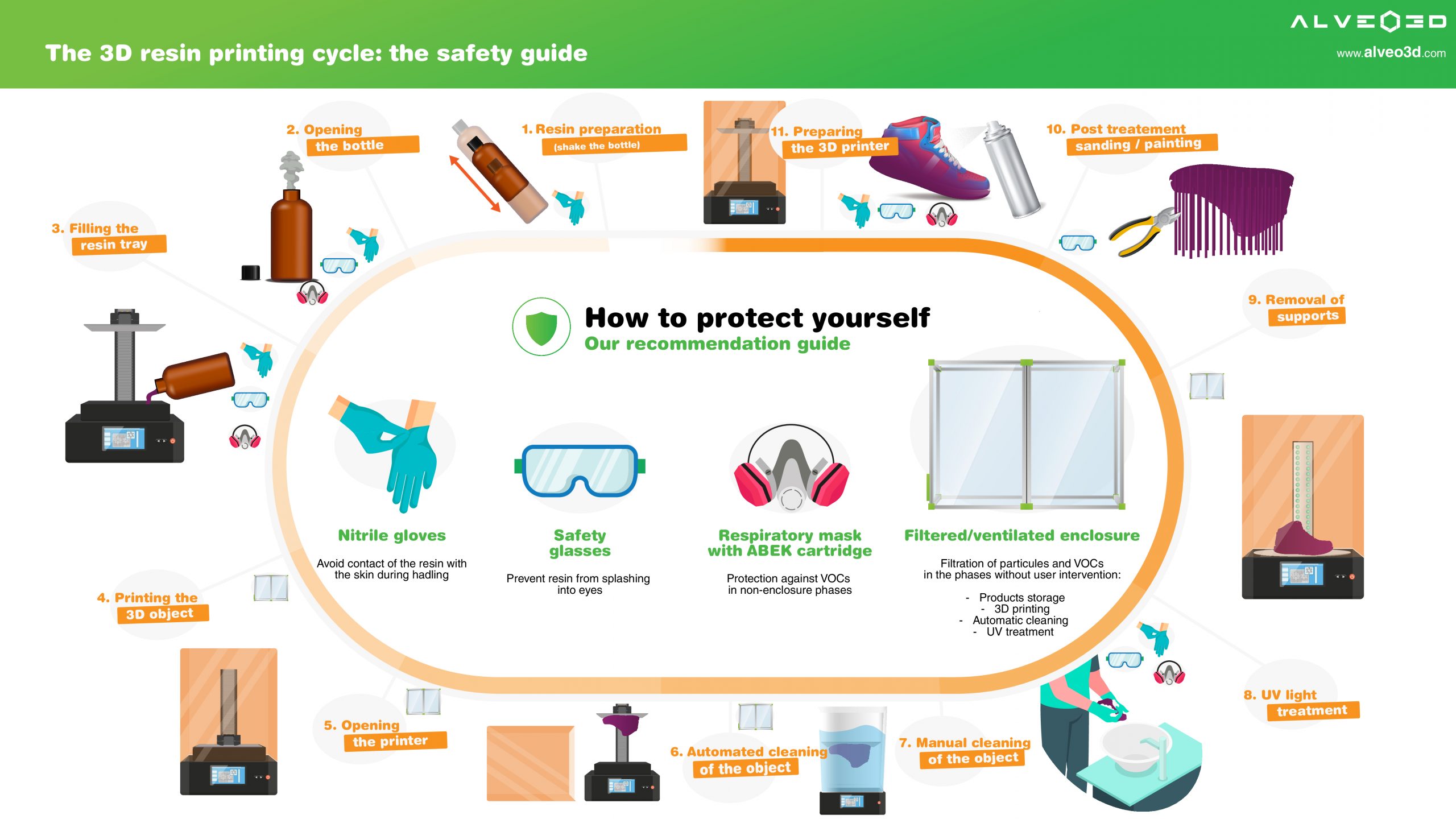

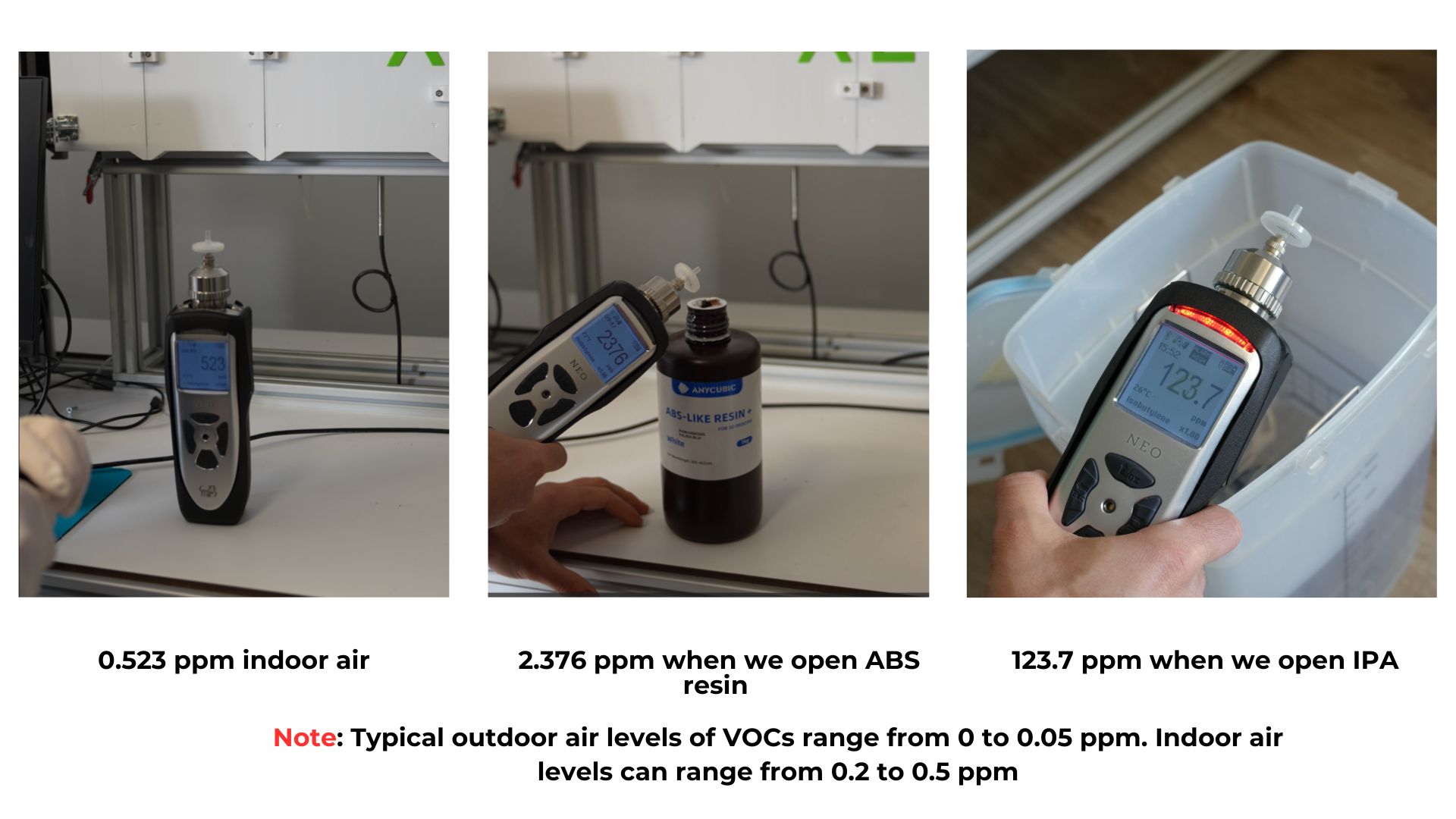

1. Volatile Organic Compounds (VOCs) from resin printing

- VOC emission: Various VOCs are released during the curing process, primarily due to the ongoing polymerization of the resin.

- Specific VOCs: The exact types of VOCs emitted depend on the specific resin formulation, but common examples include:

- Styrene: A common VOC with a noticeable odor, potentially causing health effects with prolonged exposure.

- Methacrylates: These monomers and oligomers are often present in resins and emit VOCs as they cure.

- Formaldehyde: Some resins may contain or release formaldehyde, a known irritant and potential carcinogen.

- Other VOCs: Depending on the resin, additional compounds like phenols and isocyanates might be present and released as VOCs.

2. Ultrafine Particles from FDM Printing

Is it safe for children to be near a machine without an enclosure, considering the risk of ultrafine particles? (Photo credit: Creality)

3. Physical safety around moving parts

- Students may be at risk of injury from the moving parts of 3D printers, such as the print head and bed.

- Limit the time spent observing the 3D printer while it is running

- Utilize remote monitoring options if available, and ensure the printer is enclosed and equipped with appropriate filtration systems to capture and neutralize VOCs and ultrafine particles

What do you think about the image above ? The little girl and boy are close to a 3D printer without any adults around while the 3D printing is still running 😟

4. Proper material handling

Handling 3D printing materials, especially resins and certain filaments, can pose health risks.

5. Missing regulations and the need for standards

Despite the increasing use of 3D printing technology in schools and other non-industrial settings, there are gaps in regulatory frameworks and safety standards specifically addressing 3D printing emissions and operational safety. In Europe, we don’t have any regulation for 3D printng safety. In the US, there are approaches to Safe 3D Printing by NIOSH. This regulatory gap poses significant challenges:

A. Lack of specific emission standards

-

- Currently, there are no universal standards regulating the emissions of VOCs and ultrafine particles from 3D printers. Regulatory bodies need to establish clear guidelines to protect users from these harmful emissions.

B. Inconsistent safety practices

Without mandated training programs, teachers and students may lack awareness of the potential hazards associated with 3D printing and the necessary precautions to take. For example, many students handle 3D resins without wearing gloves or safety glasses. This lack of awareness is problematic because many 3D printing resins do not have strong odors, leading people to mistakenly believe they are safe to handle directly.

-

- Handling without PPE: Students often handle resin without gloves or protective eyewear, exposing themselves to potential skin irritation and chemical burns. Resin can be highly toxic, and direct contact can cause significant health issue

- Misconceptions about safety: The absence of a strong smell in some resins can create a false sense of security. Users might not realize that these materials can still release harmful VOCs and other toxic substances during the printing and curing process.

III. Best practices for safe 3D printing in schools

Ensuring that learners recognize the risks associated with 3D printing is essential before delving into the technical aspects, materials, and techniques.

1. Enclosures and Ventilation

-

- Ensure all 3D printers are enclosed to contain emissions and prevent physical contact with moving parts.

- Install adequate ventilation systems to dilute and remove harmful emissions from the printing area.

- Open the window to ventilate the air in the enclosed space.

- In the winter, it is crucial to maintain an enclosure.

- The enclosure must have a 3D filtration system

Credit photo: Chemical Insights: Chemical Pollutant Safety

2. Regular maintenance and filter replacement

-

-

- Schedule regular maintenance checks for all 3D printers.

- Replace HEPA and activated carbon filters as recommended by the manufacturer to ensure they remain effective. Alveo3D recommends replacing the HEPA and activated carbon filters every 6 months if you print infrequently, and every 3 months for intensive printing.

-

3. Education and training

-

- Educate students and staff about the potential risks associated with 3D printing and the importance of safety measures.

- How to read and interpret MSDS Material Safety Data Sheets for 3D printing materials

- Identifying and mitigating risks associated with different materials (ABS, PLA, ASA, Resin, etc)

- Checklist usage and compliance

- Provide hands-on training for safe printer operation and emergency procedures, such as gloves and safety goggles

4. Monitoring and compliance

-

- Monitor the air quality in the printing area to ensure it meets safety standards.

- Ensure compliance with local regulations and guidelines related to 3D printing safety.

IV. Conclusion

In fact, Alveo3D has received many questions about the risks of 3D printing emissions from many universities in Europe and the US. We are really concerned about this issue. While the current regulations might seem limited, ensuring the safety of 3D printing in schools is crucial to protect students from potential health risks.

By implementing proper ventilation, using enclosures, educating students on safety practices, and maintaining equipment, schools can provide a safe and engaging environment for exploring 3D printing technology. As the popularity of 3D printing in educational settings continues to grow, prioritizing safety will help foster a healthy and innovative learning atmosphere.

References:

- https://ehs.osu.edu/sites/default/files/documents/3D-Printer-School-Safety-2020.pdf

- National Institute for Occupational Safety and Health. (2024). A Guide for Makerspace Users, Schools, Libraries, and Small Businesses. Retrieved from https://www.cdc.gov/niosh/docs/2024-103/pdfs/2024-103.pdf