- Visual quality 65%

- Tensile strength 20%

- Elongation at break 65%

- Impact resistance 65%

- Heat resistance 80%

- Moisture resistance 80%

- Interlayer adhesion 45%

- The durability index 10%

- Emissions (Nanoparticles + VOCs) 100%

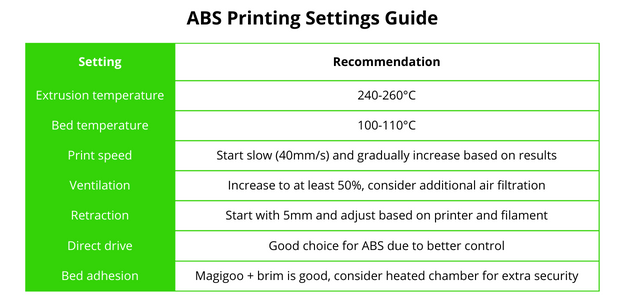

| Printing ABS for: |

|

However, it’s important to be aware of the potential health risks, ecological impact associated with using ABS filament. In this blog, we will dive into the health risks associated with using ABS plastic in 3D printing. Our goal is to show you what you need to know to print ABS safely and responsibly.

Air inlet grille printed with ABS filament

II. Are ABS fumes toxic?

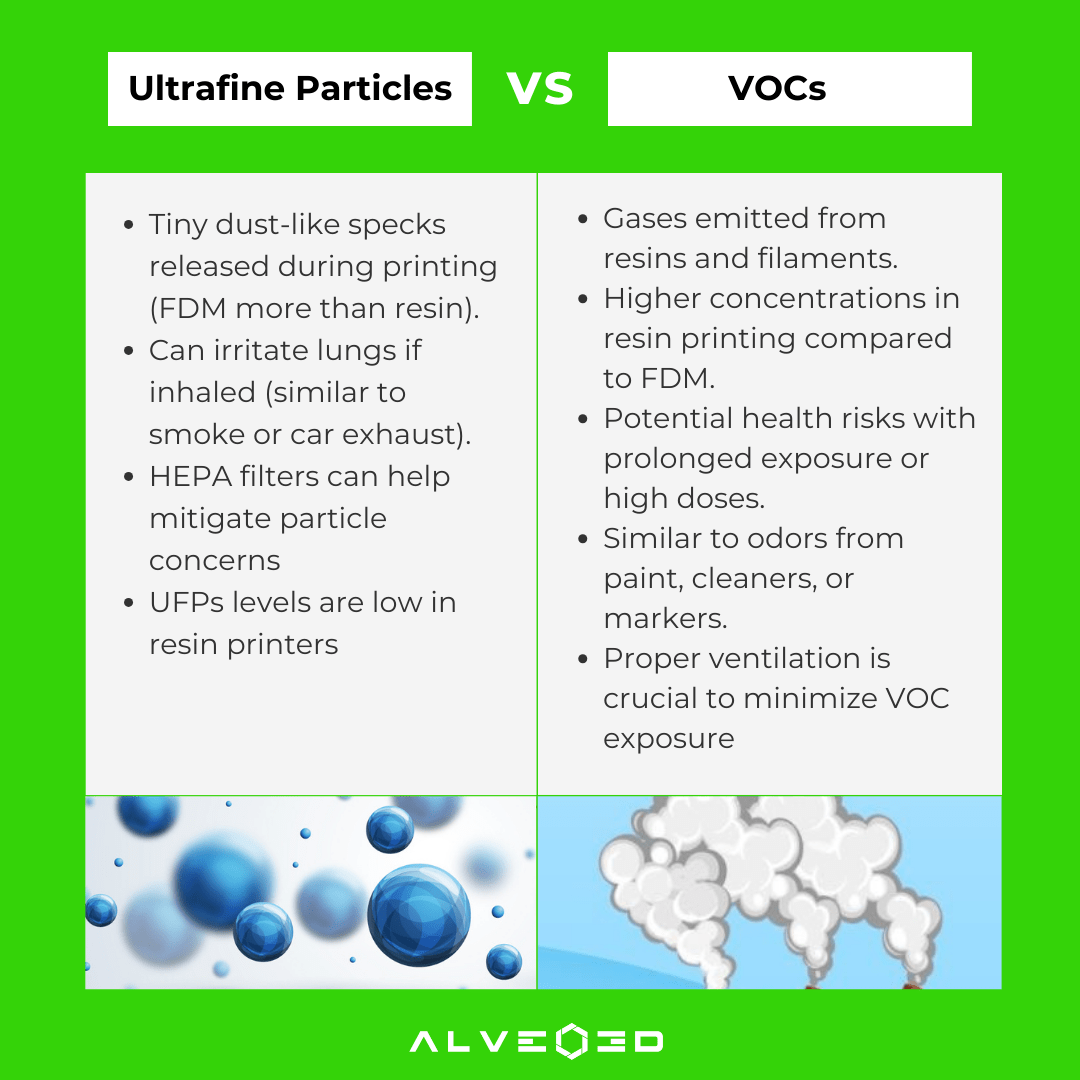

According to NIOSH, there are potential health risks associated with ABS fumes released during 3D printing. NIOSH states that during 3D printing with ABS, the plastic filament heats up and releases ultrafine particles smaller to 100nm and VOCs.

The size of these particles is a cause for concern because they are small enough to be inhaled and absorbed into the lungs. Studies have shown these emissions can cause moderate toxicity in human lung cells.

ABS plastic is dangerous to our health:

- Fumes from processing: When ABS plastic is heated to high temperatures, such as during 3D printing or manufacturing processes, it can release fumes that can irritate the eyes, throat, and respiratory system. These fumes may also cause headaches, nausea, and dizziness.

- Burning ABS: ABS fumes can be harmful if inhaled and can cause serious health problems, including respiratory failure.

- Skin contact: Prolonged or repeated expose to ABS plastic can irritate the skin.

As expertise in 3D printing emission, we recommend a few ways to reduce the risk of exposure to ABS fumes when 3D printing:

✅Place printers in a well-ventilated area

✅Use a HEPA+ Actived carbon air purifier: A HEPA air purifier can help to remove ultrafine particles less than 100nm

✅Reduce printing time: The longer you print, the more fumes you will be exposed to.

✅Use low-emission filaments whenever possible: Consider using a filament that releases fewer fumes, such as PLA

✅Enclose the printer: This will help to contain the fumes and prevent them from spreading throughout the room

III. Numbers on ABS plastic health risks in 3D printing

- 250°C – 300°C: This is the typical printing temperature range for ABS filament, during which harmful particles and volatile organic compounds (VOCs) are released.

- Styrene: 50 ppm (TWA), 100 ppm (STEL): Styrene is a major VOC emitted by ABS and is classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC). These numbers represent the Time-Weighted Average (TWA) and Short-Term Exposure Limit (STEL) set by OSHA for safe workplace exposure

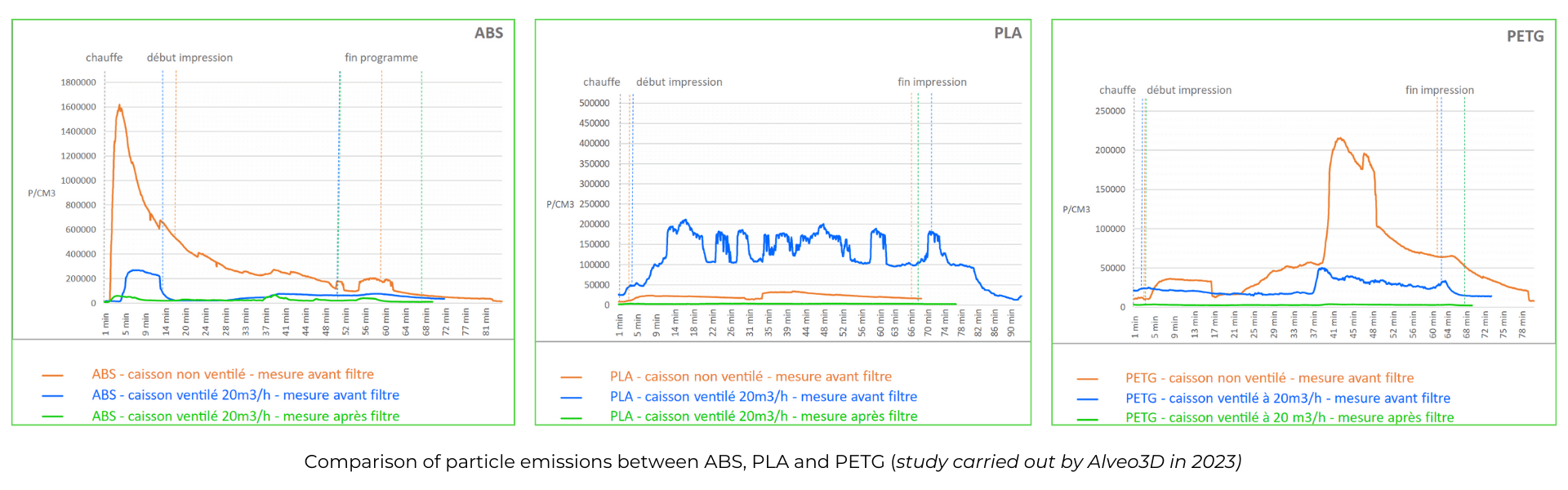

- 200 to 300 times more particles than common air pollution, which is significantly higher than PLA and PTEG confirmed by Alveo3D’s study

- Ultrafine Particles (UFPs): < 100 nm: These tiny particles can bypass the lungs’ natural defenses and enter the bloodstream, potentially causing respiratory and cardiovascular issues. Studies of National Institute for Occupational Safety and Health (NIOSH) have shown elevated UFP levels during ABS printing.

IV. 3D printing ABS safety guidelines

Ventilation is vital in 3D printing.

- Open windows and doors: Maximize fresh air circulation in your printing space. But, if we are in winter, we have to think about filtration system

- AlveoONE & R: Mountable air filtering systems for individual printers, capturing fumes and particulates.

- PrinterCase: All-in-one enclosed printer with a built-in filtration system.

- Custom Enclosed Printer: Provides a sealed environment with ventilation and filtration for larger printers.

3D printer in our workshop equipped with enclosure and filter AlveoOne in open space

Personal Protective Equipment (PPE):

- Respirator: Wear a respirator with activated carbon filters rated for organic vapors and particulates when operating the printer.

- Gloves: Protect your hands from potential skin irritation.

Other Measures:

- Monitor air quality: Use air quality monitors to track VOC and UFP levels, adjusting ventilation accordingly.

- Minimize printing time: Reduce exposure by optimizing print settings for efficiency.

- Consider alternatives: Explore safer filaments like PLA or PETG when possible.

- Avoid touching the hot bed or extruder: These components reach high temperatures during printing and can cause burns.

- Never leave the printer unattended while printing: Monitor the printing process to ensure everything is functioning properly.

V. Is ABS the only option?

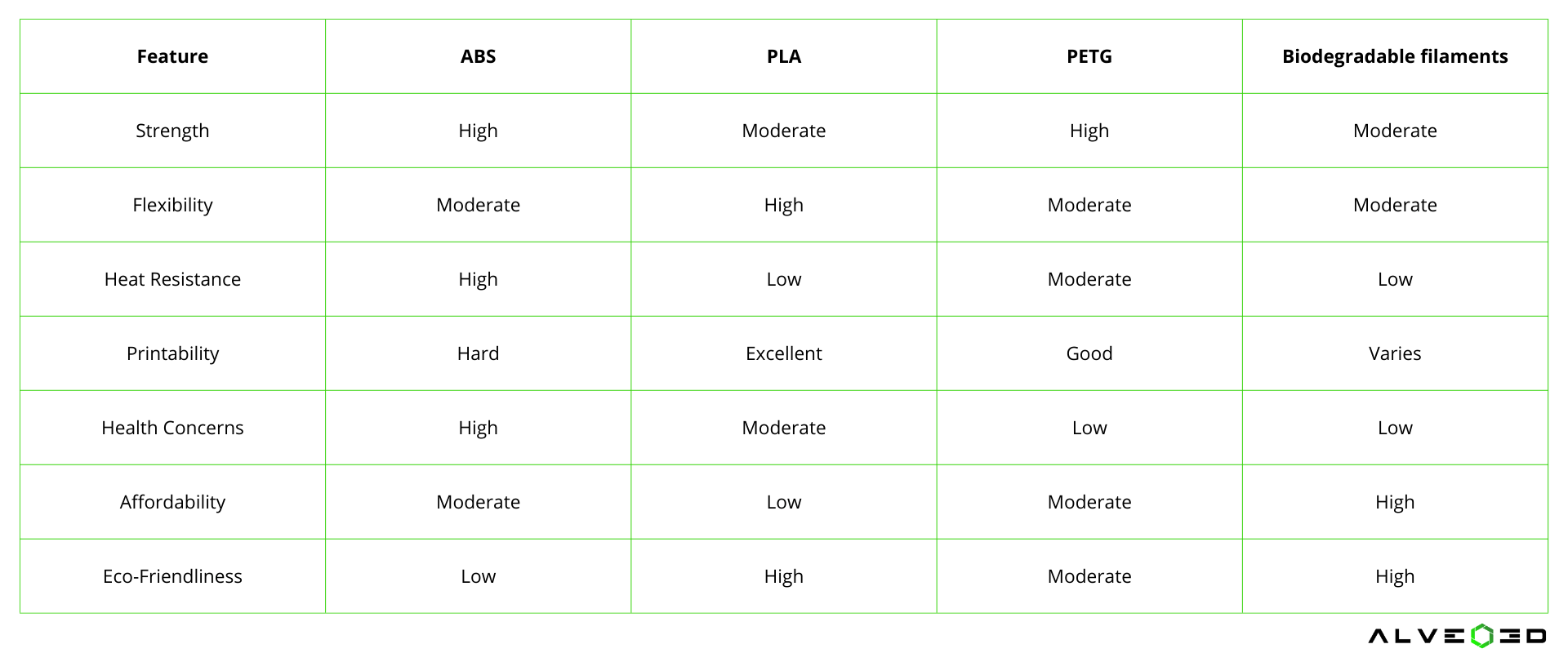

Not really! While ABS offers a lot of advantages, its health concerns can’t be ignored. The release of VOCs like styrene and ultrafine particles during printing necessitates meticulous safety measures. Fortunately, several alternatives offer comparable performance with a significantly lower health footprint.

- PLA (Polylactic Acid): PLA is recyclable, biodegradable and compostable. But that doesn’t mean the ocean or any other natural environment can handle it easily. But it is safer than ABS. However, its strength and heat resistance are lower compared to ABS.

- PETG : Offering a middle ground, PETG combines some of ABS’s strength with improved heat resistance compared to PLA. It’s food-safe and emits fewer fumes, making it a popular choice for functional parts and food-related applications.

- Biodegradable Filaments: Bio filaments like polyhydroxyalkanoates (PHAs) and bamboo offer an eco-conscious choice. Their printability and properties vary, but they degrade naturally, minimizing environmental impact.

Here’s a quick comparison between ABS, PLA, PETG and Bio filaments:

VI. Future of 3D printing materials

1. Does ABS consume more energy than other materials?

In comparison, ABS requires more energy to print than materials like PLA due to its higher printing temperature. The ABS printing process requires temperatures typically between 210 and 250°C, which is higher than the printing range of PLA. This higher temperature requirement causes ABS to consume more energy during the 3D printing process

2. Alternatives to ABS 3D printing

ABS plastic can be recycled, but it has some challenges and limitations compared to other materials. Here are better options:

Sustainable materials:

- Biodegradable and bio-based filaments: These filaments, made from natural materials like PLA, wood, or bamboo, offer eco-friendly alternatives with comparable printability.

- Recycled materials: Utilizing recycled plastics or metals for filaments can reduce waste and environmental impact.

- Circular economy models: Developing closed-loop systems for material reuse and recycling within the 3D printing industry.

Biocompatible materials:

- Medical-grade filaments: Advances in materials like PEEK and bioresorbable polymers enable printing of implants, prosthetics, and other medical devices with improved biocompatibility and patient safety.

- Tissue engineering and regenerative medicine: 3D printing with biocompatible materials holds potential for creating personalized tissue constructs for transplantation and regeneration.

- Focus on non-toxic and hypoallergenic materials: Minimizing the risk of allergic reactions and skin irritation associated with some filaments.

Source of photo: Beyond Plastic

VII. Conclusion

Overall, ABS remains a valuable filament for specific applications due to its unique advantages. However, it’s crucial to be aware of its drawbacks and take necessary precautions when you print with it. More than that, ABS is not biodegradable like PLA and can contribute to plastic waste.

Last but not least, don’t forget to following your guidelines and being mindful of the potential health risks, you can enjoy the benefits of ABS printing while protecting your health.

Resources:

- Lakhan, S. E., & Vieira, K. F. (2008). Nutritional therapies for mental disorders. Nutrition Journal, 7(2), 1-7. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10818734/

- National Institute for Occupational Safety and Health. (2024). A Guide for Makerspace Users, Schools, Libraries, and Small Businesses. Retrieved from https://www.cdc.gov/niosh/docs/2024-103/pdfs/2024-103.pdf