Is the danger of fine or nanoparticles from filament 3D printers real? If I leave my window open, am I safe? Yes, but the outdoor air may be polluted, especially if I live in the city, so what about my health?

First of all, let’s start with a small definition. What are fine particles?

A cloud of particles that we can’t see, does not mean that the air is clean. Regarding fine particle pollution, they are smaller than a micrometer in size. In the air quality field, these particles are studied using the PM (Particulate Matter) classification.

PM 10 – particles smaller than 10 micrometers

PM 2.5 – particles smaller than 2.5 micrometers

For comparison, the diameter of a hair is between 50 and 100 micrometers.

Under 0.1 micrometer (or 100 nanometers) the term nanoparticle is used. The term Ultrafine Particles (UFPs) is also used to refer to these nanomaterials. They have a size between that of an atom and a cell. Of course, a 105 nm particle will also be a nanoparticle, an order of magnitude.

Small reminder: 1 micrometer = 1000 nanometers.

So, a PM 2.5 corresponds to a 2500 nm particle.

They are widely used in the cosmetic and food industries. For example, you may know E171 from the ingredient list. These are titanium dioxide nanoparticles used for whiteness: toothpaste, chewing gum, sunscreen, candies…

II. Fine particles and health risks ?

Risk = danger X exposure

Exposure refers to the number of particles in a volume that can be inhaled and that is measurable. By using a filtration system, exposure can be limited. However, the danger of nanoparticles is still not fully understood and refers to the impact on health from a specific particle.

Regarding PM10 and PM2.5 fine particles, they cause well-known negative effects on health. The increased risk of cardiovascular diseases, impaired lung function, and carcinogenic effects have been shown. In general, they reduce life expectancy.

III. The specific risks of nanoparticles

They are well present, but the extent of the problem is not well known yet for all nanomaterials.

However, there is a slight problem with measuring air pollution.

The current legislation proposes a framework for emissions of particles at best PM2.5, especially during periods of peak atmospheric pollution. And in this context, the mass of fine particles in suspension is measured in micrograms per cubic meter.

However, the 3D printer nanoparticles emitted are 10 to 100 times smaller. For an equal mass of material, they will be much more numerous. This decrease in size and increase in number will optimize their toxicity potential. Yet they will not be accounted for.

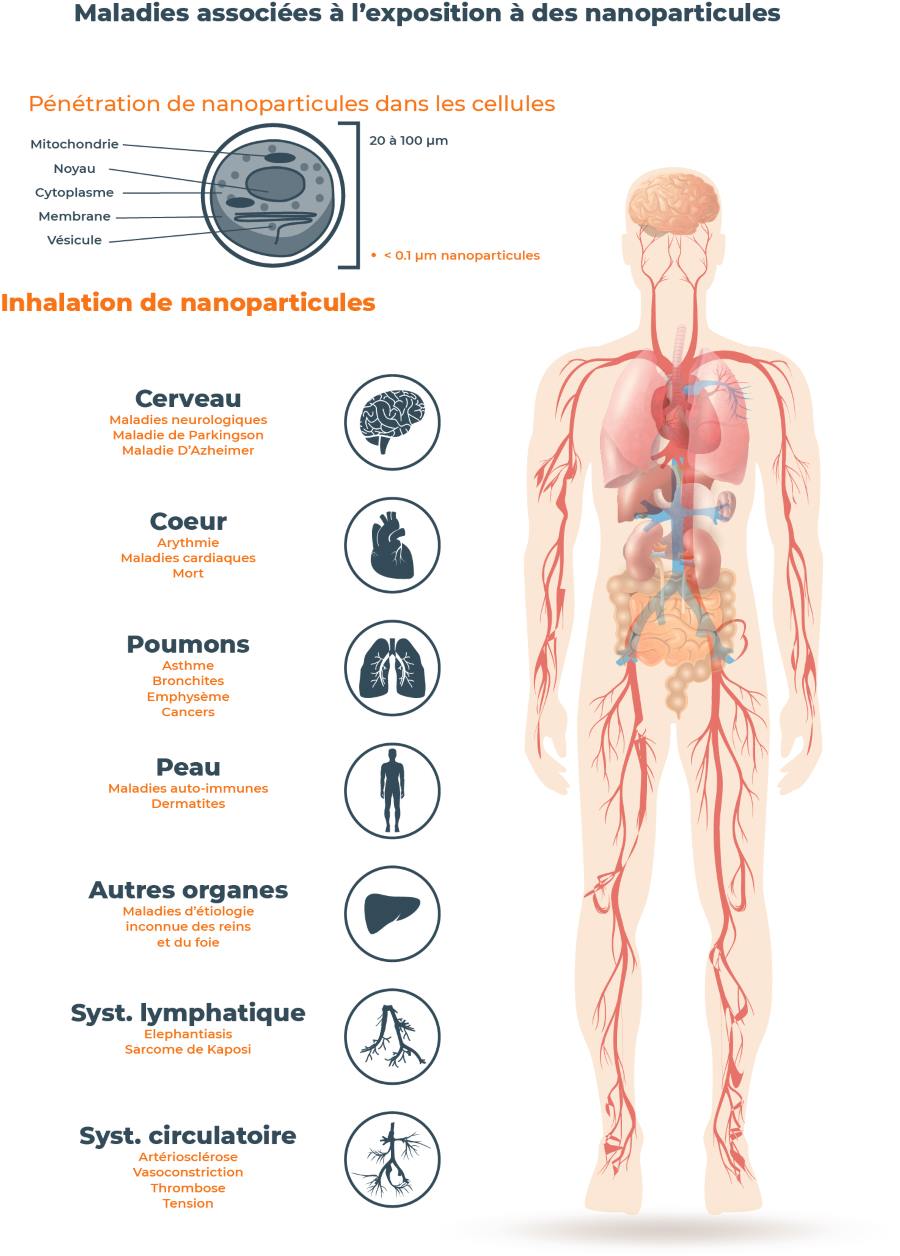

The thinness of these particles will allow them to be lodged deeply in the human body, reaching the lungs, the blood, the internal organs, and the brain.

Thus, the physicochemical properties of the same material are very different between a nanoparticle and a fine particle.

A material that is harmless at “normal” size may not necessarily be harmless at “nano” size. Therefore, all toxicological studies must be redone when materials are in the form of nanoparticles.

The Cancer Research Center indicates that “the biopersistence of nanomaterials raises fears of chronic toxicity or even the development of cancers with the combination of genotoxicity and chronic inflammation.”

Not very reassuring to hear, but it is best to be informed to better anticipate. The study “Nanomaterials and nanoparticles: Sources and toxicity” illustrates the potential effects of nanoparticles at all levels of the human body.

IV. Harmful emissions in 3D printing

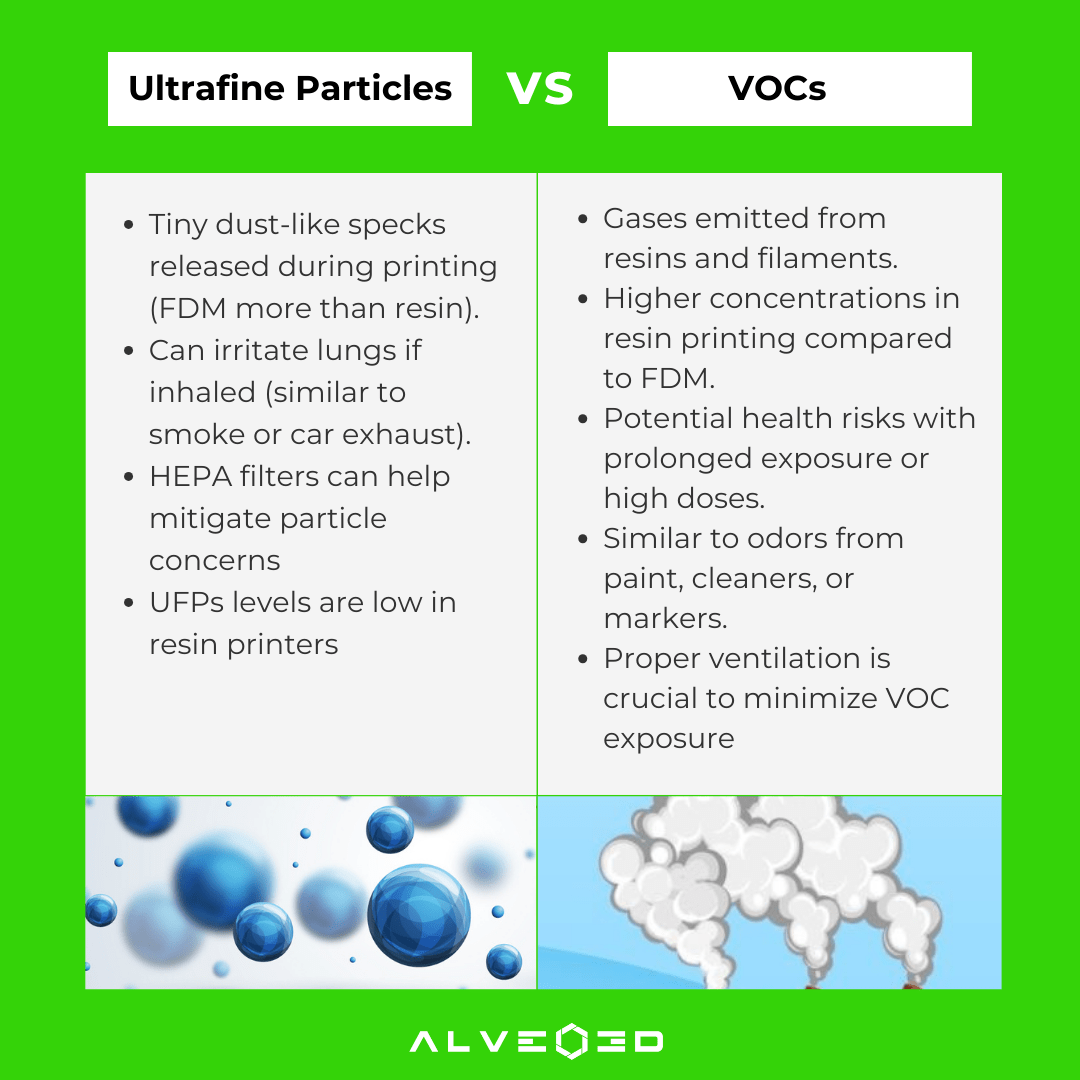

Depending on the filament and extrusion temperature, 3D printers emit particles of different sizes and types. It is during the extrusion of plastic that particles are released in large quantities.

An increased extrusion temperature will emit more particles. Therefore, thermoplastics based on petrochemical products like ABS emit more particles than those made from natural organic compounds like PLA.

In 2013, the Illinois Institute of Technology measured the proportion of 3D printer nanoparticles. There are 20 to 100 times more nanoparticles from 10 to 116nm (gray dots) than particles beyond 116nm (orange dots).

The nanoparticles are not only more numerous but also lighter. The larger particles are also heavier. The filtration mechanisms will be different depending on the size and mass of the particles.

This graph provides more information about particle emissions. It shows that the air already contains nano and microparticles before any use of 3D printers. It also reveals:

- Printing with PLA did not release any particles larger than 116 nm

- In 20 minutes, 2 PLA printers increased the concentration of nanoparticles by 5 times

- The concentration of nanoparticles seems to increase much more quickly in the presence of ABS

- The rate of nanoparticles decreases slowly after printing has ended

V. Which filter for nanoparticles?

There are filters specifically designed to treat fine particles. In the industry, we find different standards for particle filtration.

We have identified the EN1822 standard. It defines the efficiency of particle filters by counting the filtered particles.

- EPA/HEPA – High-Efficiency Filters

- ULPA – Low Penetration Filters

This standard is ideally suited to the context of 3D printing environment filtration and is comparable to working in clean rooms (laboratory, electronics…).

Regarding protection, it is common to consider the worst-case scenario.

In the EN1822 standard, a filter is defined for the highest penetration particle size efficiency (MPPS), meaning the particle that will best pass through the filter. And it’s not necessarily the smallest one.

The filter is not just a simple sieve with holes where all objects bigger than the holes are captured.

Each HEPA filter has an efficiency profile based on the particles’ size.

In the filter performance curve, you will notice that the lowest filtration point is not for the finest particle 10nm (0.01 micrometer). The most penetrating MPPS particle is around 300 nanometers; the lowest efficiency will be 99.95%. For particles above the MPPS, the efficiency is absolute. Below the MPPS, efficiency approaches 100%.

For example, a HEPA13 filter will capture at least 9995 out of 10,000 particles of a size of 0.3 micrometers, while a HEPA14 will capture 9999 out of 10,000.

Very High-Efficiency filters with this profile can therefore effectively capture nanoparticles starting from 10nm emitted by 3D printing with very high efficiency.

VI. Filter nano and micro particles

It’s a matter of mass. We’re talking about particles that are so small that gravity or inertia doesn’t have the same impact. Four filtration mechanisms come into play.

Diffusion

Ultra-fine particles smaller than 0.5 micrometers are so light that they vibrate with the material without perfectly following the airflow (Brownian motion).

Interception

Inertia

Screening

Thus, it is primarily the diffusion mechanism that will allow nanoparticles to be retained in the filter fibers.

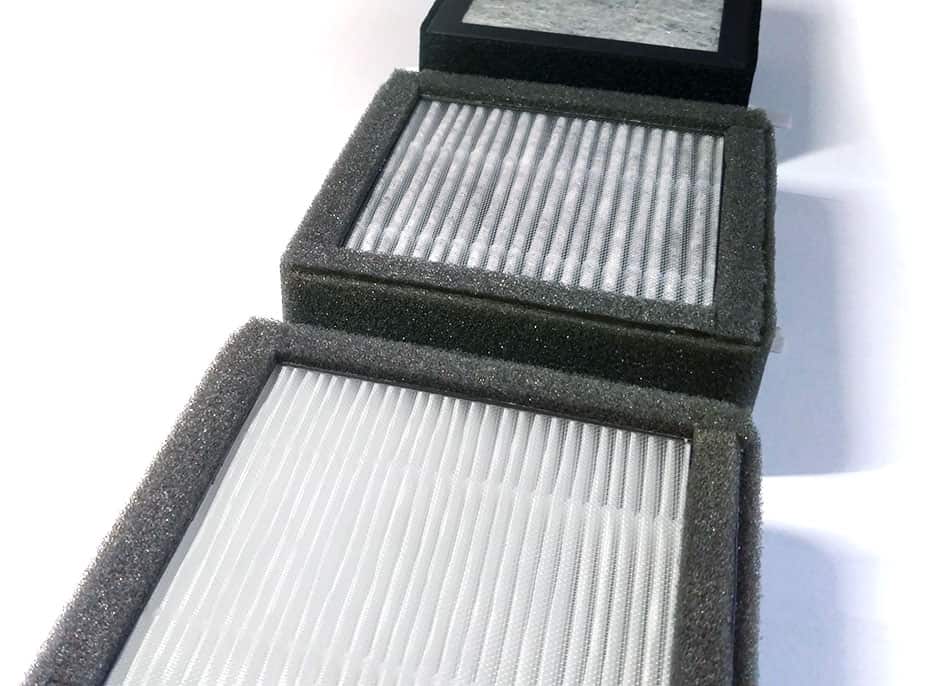

VII. Choosing the Alveo3D Filter?

You probably understand by now that the perfect filtration system for 3D printer nanoparticles does not exist.

But we want to offer the most effective solution possible. The main work in selecting the type of filter is to find the right balance between 3 variables: Efficiency / Air resistance / Cost

We mentioned the efficiency of the HEPA filter and it is naturally towards this type of material that we turned. The choice to use certified filters that meet the EN1822 standard to ensure real efficiency on fine particles naturally imposed itself.

The filters are tested for their overall efficiency (average performance of the entire filter) and for their local efficiency (performance at different points on the filter surface, except for HEPA filters). We quickly determined that we wanted to use a minimum HEPA13 filter to ensure very high efficiency regarding nanoparticles.

HEPA filters were set aside due to their limited performance and the lack of local value testing. According to INRS recommendations, HEPA filters are designated to provide effective protection during 3D printing.

VIII. So HEPA 13, HEPA 14 or ULPA 15 ?

The Alveo3D lab tested all 3 filter types. To choose the right filter, it is necessary to know or test the pressure drop it will generate, i.e. its air resistance. Then, the ventilation system can be calibrated based on this resistance.

So ULPA filters quickly showed very high resistance. We can not make a compact and relatively quiet ventilation system for 3D printing with this type of filter. We now know why they are called “low penetration filters”. They are also more expensive.

Thus, the decision would come down to between HEPA 13 and HEPA 14 filters.

A HEPA filter can be made with pleats to increase the filter surface area. A larger filter surface area reduces air resistance and increases the filter’s lifespan.

We experimented with around 20 prototypes, altering the thickness of the filters and using different filter materials such as glass fiber, polyester fibers, and charcoal-infused fibers.

Our goal was to allow the filtration of 3D printer nanoparticles from a 60x60x60cm cabinet in 30 seconds, with a flow rate of 26m3/h. This flow rate must be achieved in a compact format with dimensions of a 120mm fan to fit the most number of cases. And finally, not to exceed the air flow rate through the filter in order not to damage its performance.

With these characteristics, the HEPA13 filter was revealed to be the best compromise: 50dB in the cabinet on average between the AlveoONE filtration kit in the free-standing version or panel mounting. The cost is reasonable. We can therefore offer the most affordable universal filtration kit on the market with very good efficiency and good life.

Resume

It would be possible to use HEPA 14, but the noise generated by the fan is not pleasant at all with the current concept. Nevertheless, we have an excellent opportunity for development with a future HEPA 14 filtration kit. Our challenge will be maintaining a reasonable noise level while increasing filtration performance.

You will find 3D printer particle filtration systems based on respiratory mask filter cartridges.

In these cartridges, particle filtration is performed by a P3 filter that meets the EN14387 standard. The filtration efficiency of these filters is similar to the HEPA 13 filter, but they are optimized for human breathing. They are designed to handle smaller volumes of air and resist humidity (which is not useful in 3D printing). They are presented in the form of small, non-pleated surfaces. This configuration offers high resistance to air and a smaller filtration surface.

Therefore, we prefer to use HEPA filters that provide a more relevant response to 3D printer nanoparticle emissions and the possibility of evolving to higher filtration levels.

3D printers also emit harmful gases called Volatile Organic Compounds COV. Find some interesting information in the INRS publications.

For more information on this topic, we recommend you the following article

Article written by:

Lucas

CEO at Alveo3D

0 Comments