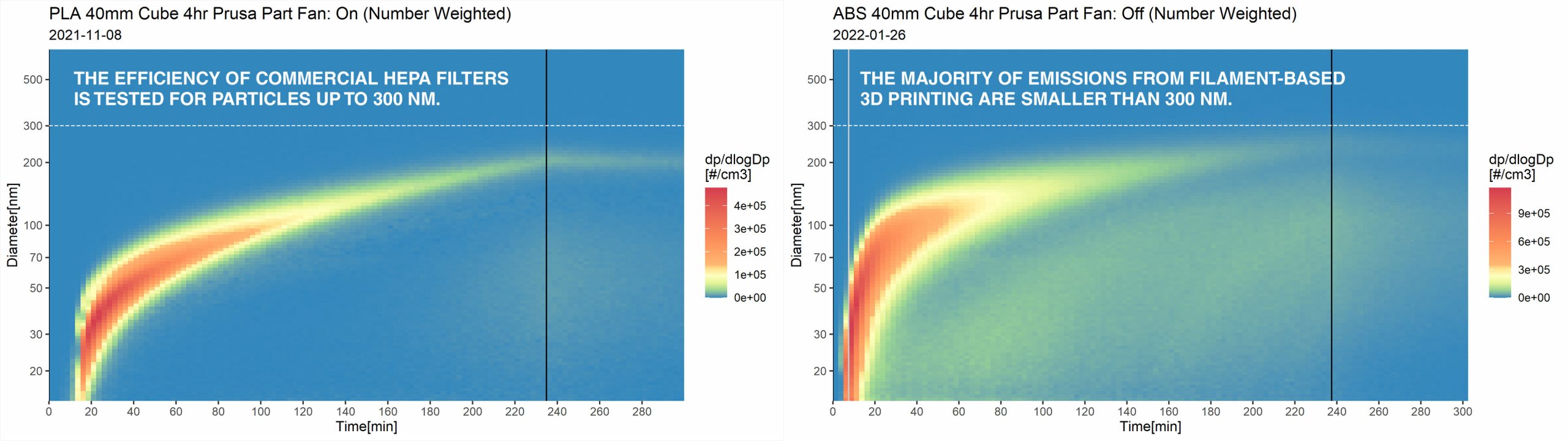

As we mentioned in our previous article “Which 3D printer filament emits the most nanoparticles?“, using 3D printer filters when printing is now essential to protect you from these toxic emissions.

To do this, we had a measuring bench specially dedicated to the study of particles emitted when 3D printing

When we conducted the study, in 2021, the measurement bench was in development and the different measures were taken manually upstream and downstream of the filter in the duct.

II. Evaluate the efficiency of the P3D filter depending on the particle concentration present in the 3D printer enclosure

To measure the efficiency of the P3D filter, we chose to test it on different filaments from PRUSAMENT and PRUSA

We determined an average efficiency rate over several series to compensate for potential measurement errors related to the reading time of the particle counter

III. Compare the efficiency of the 3D printer filter depending on the filament and on the airflow

- ABS is printed at a higher temperature than PETG, which is itself printed at a higher temperature than PLA

- We find the same hierarchy when it comes to the filtration efficiency, which seems to confirm that high extrusion temperature generates smaller particles (smaller than 100 nm), which reduces the filtration efficiency

- However, we cannot determine to what extent filament composition and extrusion temperature influence the size of the particles emitted. In this case, a granulometric analysis of the particles might be relevant.

In general, a filament with a higher extrusion temperature emits more particles. However, this is not always the case. Polycarbonate is printed at a higher temperature than ABS (275°) but it is not more emissive. To complete our results, we will soon conduct additional tests on other filaments.

IV. What about filament change ?

Based on our measurements during filament change, we notice several specific phenomena:

- Particle production is fast and important as soon as the extruder is heated.

- With ventilation, high particle concentrations are significantly reduced in the enclosure: now it only takes about 5 minutes, for more than 20 minutes without using it.

- The peak of particle concentration occurs about 2 minutes after the filament change. This can be explained by the reading latency of the particle counter.

V. Our recommendations

We have tested the effectiveness of fast ventilation. In the following scenario, a printing defect is detected which requires a quick stop of the manufacturing process followed by access to the printer. Activating fast ventilation (100% of the ventilation power, i.e. 40 m³/h) allows the particle concentration to be reduced from 500,000 p/cm³ to less than 10,000 p/cm³ in 4 minutes.

Thus, we recommend that operators:

- Favor low-emission filaments such as PLA.

- Use air filtration continuously since air pollution levels are systematically exceeded when printing.

- Have the fan and printer control interfaces accessible outside the enclosure to avoid exposure when printing.

- Reduce your exposure time. Once the printing is done, it is also recommended to close the chamber with the ventilation on. Since very few studies prove the effects of nanoparticles in terms of toxicity on the human body, it is difficult to say at what level of particle concentration it may become toxic to one’s health.

Therefore, it is important to apply a precautionary principle by limiting exposure time, especially when accessing the printer when changing filaments and at the end of the printing process.

Ventilation recommendations (P3D filter)

- ABS: 80% ventilation until printing begins. 30 to 40% throughout the printing and until the bet cools down.

- PETG/PLA: 80% ventilation until printing starts. 50 to 70% during printing and until the bed cools down.

At the beginning and end of the print cycle, you can also quickly drain your printer if you need immediate access to it

High pressure fan by alveo3D

VI. When should the P3D printer filter be changed?

- Use of highly emissive filaments such as ABS

- High filtration temperatures (45 to 60°C)

- Humid environment

As long as the filters are kept in their original packaging, not being exposed to sunlight and humidity, their efficiency will not be altered and they may be used up to one year after purchase

However, once the filter is out of its packaging, it will start to saturate and its efficiency will be reduced after 6 months of exposure to the natural environment

0 Comments