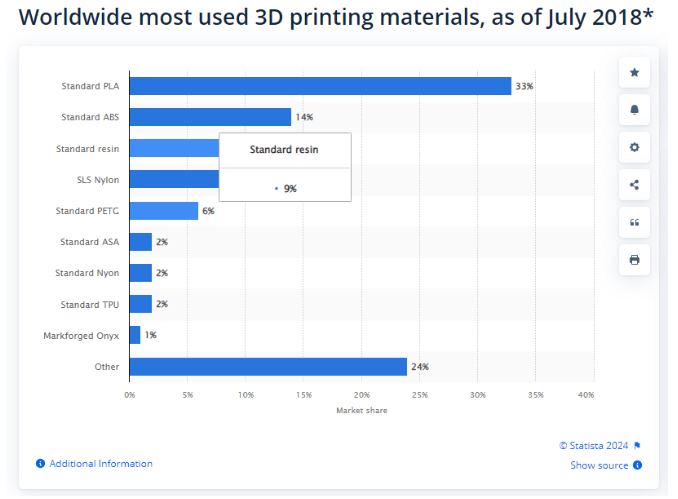

I. PLA filament

PLA is the most commonly used material in 3D printing, because of its many advantages. PLA is relatively easy to print with, as it has low warping and good adhesion to print surfaces, resulting in smoother prints with minimal distortion. Furthermore, PLA comes in a wide range of colors and finishes, allowing for creative freedom in design. However, it’s important to be cautious about PLA filament fume.

Source statista.com

While PLA seems to be a safer option compared to some other materials used in 3D printing, there haven’t been many long-term studies on its health effects. Recently, our study has shown that the process can release a lot of microparticles and COVs

II. Is PLA filament toxic ?

PLA filament itself is considered non-toxic. It is made from renewable materials, such as corn starch, and is used in a number of pharmaceutical and food packaging applications. However, it’s important to note that while the filament itself is non-toxic, some additives or dyes are used in certain PLA, we need to be cautious of PLA fumes in 3D printing.

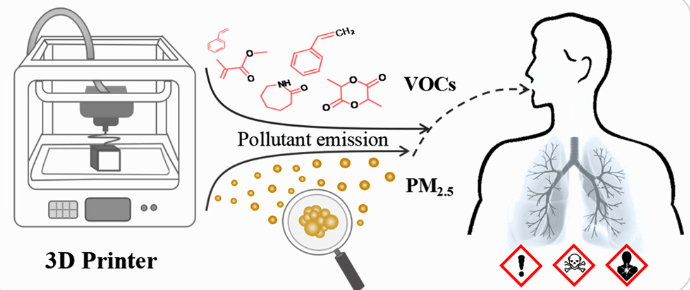

1. Generation of fumes during 3D Printing

While 3D printing offers numerous benefits, the process does involve the heating and melting of filament materials, leading to the generation of fumes and particles. PLA (Polylactic Acid) is often considered a safer alternative to other materials like ABS, but concerns still exist regarding potential health risks associated with inhaling these fumes.

2. Health effects of inhaling PLA fumes

Several factors raise concerns about the health effects of inhaling PLA fumes:

- Potential Toxicological Effects: Although studies are currently limited, some research suggests potential short-term respiratory irritation from prolonged exposure to PLA fumes. Long-term effects are unknown and necessitate further investigation.

- Ultrafine Particles (UFPs): Studies have detected the emission of UFPs during the 3D printing process with PLA. These tiny particles can penetrate deep into the lungs and potentially pose health risks due to their size and ability to enter the bloodstream.

- Volatile Organic Compounds (VOCs): PLA releases lactide, a VOC, when heated. While generally considered non-toxic in low concentrations, some individuals may experience respiratory irritation or other health effects with prolonged or high-level exposure.

- Comparison with ABS Fumes:

It’s important to contextualize the level of concern regarding PLA fumes by comparing them to other commonly used materials like ABS:

- ABS fumes: Known to emit styrene, a hazardous VOC classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC). Exposure to ABS fumes can lead to various health problems, including respiratory irritation, headaches, dizziness, and even neurological effects.

- PLA fumes: While concerns exist, the potential health risks of PLA are generally considered less severe compared to ABS due to the absence of known carcinogens like styrene. However, the presence of UFPs and potential for respiratory irritation remains a concern.

III. PLA fumes and health risks

While several studies have suggested that the ultrafine particles (UFPs) released by PLA may not pose significant chemical risks, it’s important to note that they still share characteristics common to other UFPs.

- Direct health effects: Studies directly investigating the health impacts of PLA inhalation are limited. However, some suggest potential respiratory tract irritation for sensitive individuals, causing symptoms like coughing, sneezing, or throat discomfort.

- Ultrafine particles, regardless of their chemical composition, are known to present potential health concerns due to their minuscule size. These particles can penetrate deeply into the respiratory system, reaching sensitive areas of the lungs and potentially causing inflammation or exacerbating existing respiratory conditions. Furthermore, UFPs have been associated with cardiovascular issues and adverse effects on overall health

- VOC release: PLA releases some VOCs while printing, though significantly less compared to filaments like ABS. Nonetheless, prolonged exposure to any VOCs, even at low levels, may cause adverse health effects, especially for those with respiratory sensitivities or pre-existing conditions.

IV. How to reduce risk of PLA fumes?

While PLA has many advantages, it’s crucial to acknowledge the potential for fume generation during the 3D printing process. Here are some measures we need to consider:

Reduce Exposure with Smart Practices:

✅ Ventilation is Key: Always prioritize printing in well-ventilated areas with open windows or doors. This promotes air circulation and disperses fumes effectively.

✅ Consider using an enclosure for your printer. This helps contain fumes within the designated space, further reducing exposure. Alveo3D offers precisely engineered enclosures that prioritize both safety and user experience.

✅ Opt for low-emission PLA filaments specifically designed to minimize fume generation. Explore the options available from reputable manufacturers.

✅ Consider implementing Alveo3D solutions. We offer a comprehensive range of 3D printing safety solutions, including enclosures on demand, filtration systems, and air quality monitoring tools, empowering you to create and innovate with confidence.

Personal Protective Equipment (PPE) is a choice:

- Respirators: Consult with a qualified professional regarding the appropriate respirator type and usage guidelines.

- Safety glasses: Protect your eyes from potential airborne particles.

Remember: Safety should always be a top priority in 3D printing. By implementing these measures and staying informed about evolving safety practices, you can embrace the exciting world of 3D printing while ensuring your well-being.

IV. 3D Printing with PLA

| Setting | Recommendation |

| Extrusion Temperature | Consult filament manufacturer’s recommendation (generally 190-220°C) |

| Bed Temperature | 40-60°C (may vary slightly depending on filament brand) |

| Print Speed | 40-60 mm/s (start slower for complex prints) |

| Ventilation | Not essential, but recommended for long prints or enclosed printers |

| Retraction | 2-4 mm (adjust based on printer and filament) |

| Direct Drive (Optional) | Not crucial for PLA, but can improve control |

| Bed Adhesion | Typically not required, but brim or raft can help for large prints or warped filaments |

- Visual quality 80%

- Tensile strength 85%

- Elongation at break 25%

- Impact resistance 25%

- Heat resistance 30%

- Moisture resistance 30%

- Adhérence inter-couches 90%

- The durability index 70%

- Emissions (Nanoparticles + VOCs) 70%

| Fields of application |

|

Enclosure of Alveo3D on demand for 3D printers

V. Conclusion

Printing with PLA filament typically produces low levels of harmful fumes compared to ABS or PETG, but there are still some precautions users should take. When PLA is heated, it releases minute amounts of COVs and ultrafine particles that can irritate the throat, nose, and eyes. People who already have respiratory issues can be especially vulnerable to these emissions.

To extract the PLA fumes from 3D printers, it is best to use them in areas with good ventilation. Windows can be opened, air purifier system like AlveoOne can be used, or printing can be done in a 3D printer enclosure. To reduce exposure, it’s crucial to avoid breathing in proximity to the printer at all times.

Sources:

- U.S. Environmental Protection Agency. (n.d.). 3D Printing Research at EPA. Retrieved from https://www.epa.gov/chemical-research/3d-printing-research-epa

- Statista. (2018). Worldwide most used 3D printing materials. Retrieved from https://www.statista.com/statistics/800454/worldwide-most-used-3d-printing-materials/