Professional 3D printers are often equipped with closed or semi-closed housing. Consumer machines are more generally deprived of enclosures. Let’s take a look at the advantages and disadvantages of an enclosure for your 3D printer, which proves to be an indispensable accessory for the operation of your machine.

I. Why buy an enclosure when you can make one from the box it comes in?

Making an enclosure from the box it came in is a cost-effective, DIY solution that can offer basic temperature control and protection. However, a bought enclosure typically provides better temperature stability, safety features like fire-resistant materials, and often includes filtration for fumes and particulates, offering more reliability and protection for both your prints and health.

Indeed, using a paper box for a DIY enclosure can pose safety risks, especially due to fire hazards associated with high temperatures from the 3D printer. The material isn’t designed to handle such heat, nor does it effectively manage fumes or particulate matter. Professional enclosures are made from materials that withstand high temperatures and are designed to ensure a safer and more stable printing environment. For better security and to minimize risks, investing in a purpose-built enclosure or using materials better suited for high temperatures and ventilation is advisable.

II. The enclosure protects against 3D printing risks

In the professional field, safety requirements are intended to protect operators from the various risks associated with the use of machines. These risks are also present for non-professional use. Since heating plates are generally above 100°C and the extruder is around 280°C, it is possible to consider the risk of burns, but there is also a danger of injury from the machine’s automatic movements. An informed user is more likely to be little exposed to these risks, but the surroundings or the public could face them.

The Alveo3D team has also identified invisible risks related to the polluting emissions of melted plastic filament. It is possible to feel unpleasant odors or even irritations when the printer is in a closed and poorly ventilated space. These emissions are related to the presence of Volatile Organic Compounds (VOCs) and Nanoparticles that are emitted during filament extrusion.

When the printer is placed in an enclosure, it is possible to contain these polluting emissions, filter them, or evacuate them outside the printing area. In this case, it is the operator who regularly uses his equipment, who is exposed to these toxic emissions the most, and the 3D printer enclosure allows for containing and filtering them.

III. Advantages of having a 3D printer enclosure

A 3D printer without an enclosure is exposed to some unpleasantness, such as dust. By protecting your 3D printer with an enclosure, you can reduce maintenance operations, especially the maintenance of moving parts and the extruder. A solid enclosure is an effective protection against all risks of shock or machine blockage by an external element.

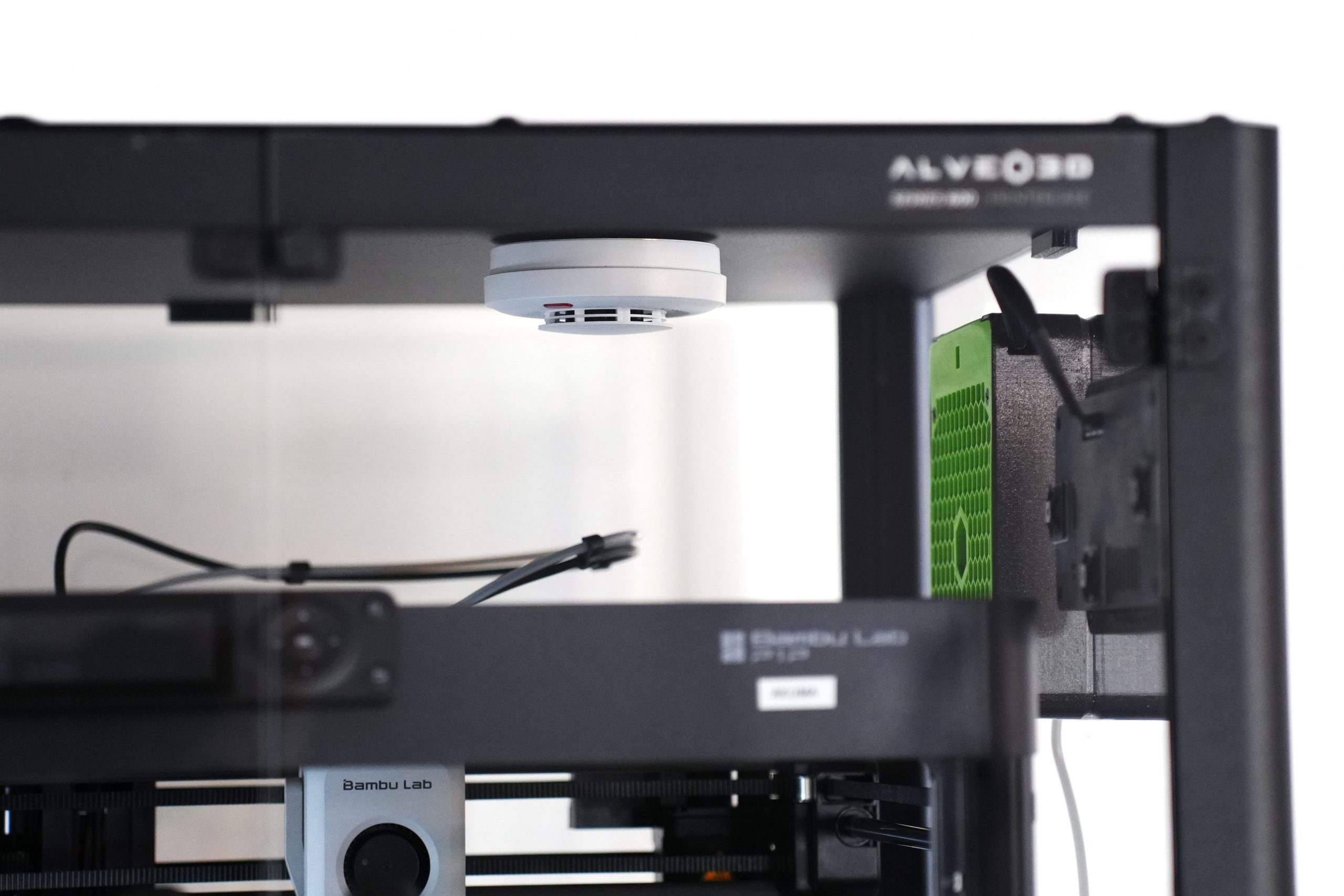

In addition, there is always a risk of fire that remains in the minds of many makers who leave the printer running for long hours. Enclosing your 3D printer will allow you to quickly detect any risk of fire by using a smoke detector and the possibility of adding an automatic extinguisher. For added safety, our custom enclosures are equipped with polycarbonate panels that can withstand higher temperatures and are difficult to ignite.

IV. Printing technical filaments, the indispensable heat of the enclosure

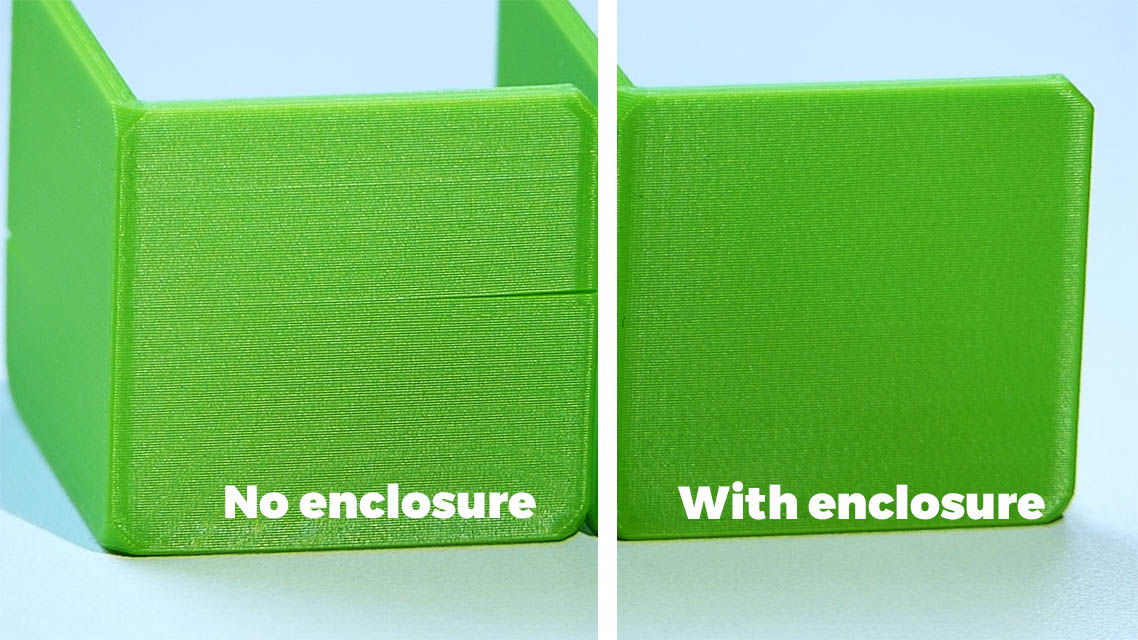

The presence of an enclosure for your 3D printer will create a warm and dry atmosphere around the printing area. You will be able to successfully print with engineering thermoplastics such as ABS, ASA, Nylon, PC, etc… By maintaining a warm atmosphere around the printing area, the effects of shrinkage will be controlled, and your prints will be successful.

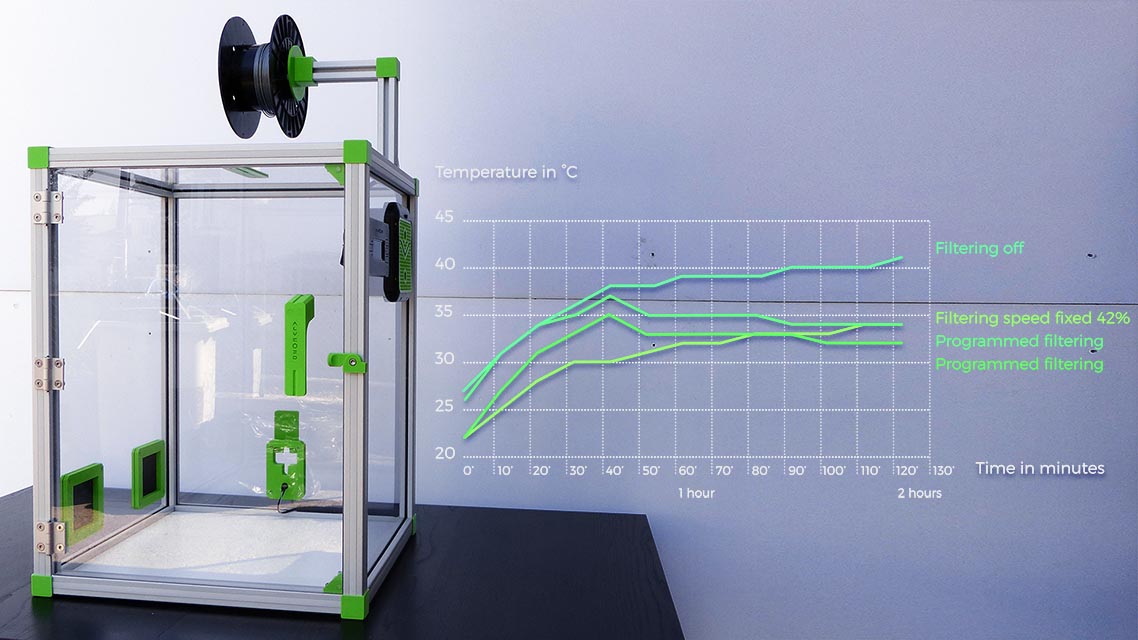

We see a temperature increase of 10 to 15°C inside Alveo3D enclosures. The speed of the air filtration systems will slightly affect this temperature, but the results are impeccable for ABS series printing.

1. Reducing Airflows Around the 3D Printer

To avoid retraction effects on all types of filaments, it is necessary to limit uncontrolled airflows around the printing area and in a closed environment, all these parasitic flows will be avoided.

Accessing the machine during a printing process requires opening the door of the printer enclosure and generates a slight airflow. Within our 3D printer farm, we have not seen any significant disturbances. Of course, these machine accesses during printing are limited to preserve the stable environment around the printing area.

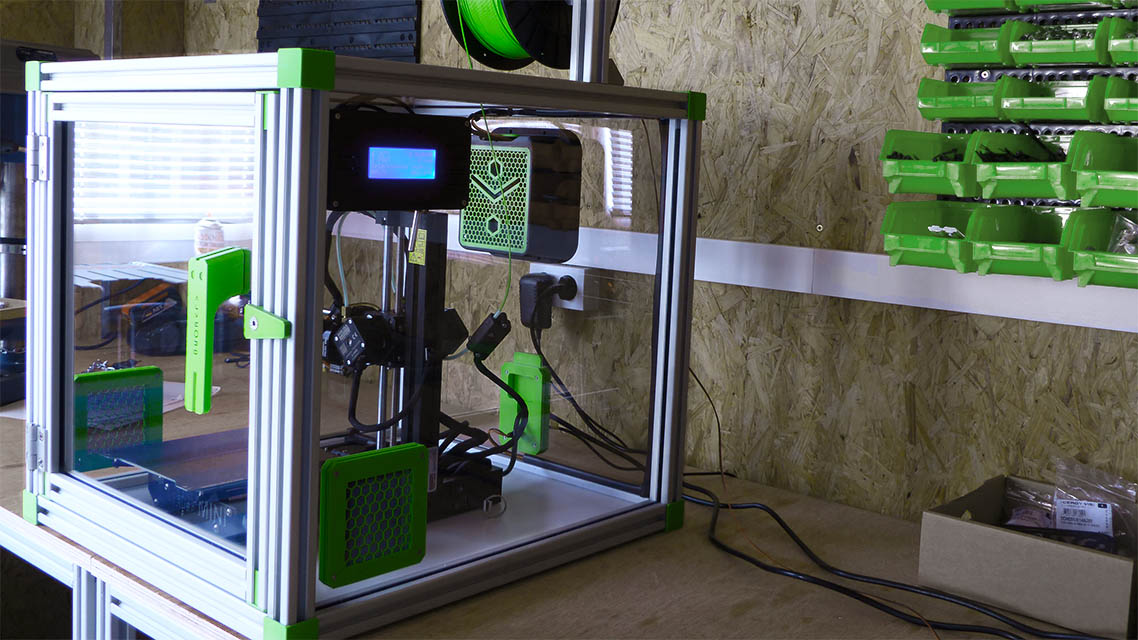

2. Optimize your workspace

The enclosure can come with its own stand and provide storage space for the consumable and tools. The height of the frame will position the printer at the right height for standing work (120cm), on a high stool (90cm), or at a sitting height of the work surface (70cm).

It is also possible to stack two enclosures on top of each other to save space. In this case, we recommend positioning the print bed of the uppermost printer at a maximum height of 120/130cm.

3. Machine accessibility

4. Loading the consumable

Changing the filament is one of these common operations that should remain simple and functional. It is possible to place the filament spool in the enclosure in order to protect it from dust and benefit from the warmer and drier atmosphere inside the enclosure. It is also possible to place the spool outside the enclosure, which can reduce the latter’s volume and allow for an increase in temperature inside the enclosure if your prints require it.

5.Visibility of prints

With a 3D printer enclosure, it is possible to lose visibility of the ongoing print, especially with the use of opaque walls. We prefer to make transparent polycarbonate enclosures to view the print from all sides. Nevertheless, it is sometimes preferable for reasons of cost, convenience or UV protection (SLA printers) to make walls that are not transparent. In this case, the presence of lighting in the enclosure will be an indispensable asset.

6. Pollutant Concentration

However, the biggest disadvantage of enclosing a 3D printer in a cabinet without a filtration system is the concentration of pollutants. COV and nanoparticle levels can quickly rise to toxic levels. For the Alveo3D team, implementing an air extraction or filtration system is essential for using a cabinet. The AlveoONE and AlveoONE-R systems are specifically designed for this application.

Excessive temperature

Among the advantages we mentioned of using an enclosure, temperature must be controlled to not exceed the technical limits of your equipment. This is one of the reasons for the presence of a temperature sensor on our V2 board (an accessory to the AlveoONE air filtration systems). Refer to your equipment’s technical sheet and verify that the temperature inside the enclosure does not exceed the manufacturer’s values, often around 50°C.

It is possible to relocate the control interface and electrical power supply of the printer to protect the equipment.

The disadvantages we just mentioned are inherent to the use of a case but can be reduced by using transparent panels, a temperature control system and by providing sufficient accessibility. The benefits brought are then essential for good productivity and the ability to print more technical filaments that require a warm and stable environment around the printing area.

The measurements made regarding nanoparticle emissions and COV toxicity prove the necessity of protecting users. This is all the more necessary for the use of 3D printers in poorly ventilated small premises. Equip your printer with a case and its air filtration system to print in peace.

Article written by:

Lucas

CEO at Alveo3D

0 Comments