The use of a filament-based (FDM) 3D printer is a source of nanoparticle emissions. Specifically, mainly particles from 10 to 100nm are emitted. For comparison, the smallest particle sizes measured to address atmospheric pollution are PM2.5, which measure 2500nm.

To measure such small nanoparticles, we use high-performance sensors that count all particles from 7 to 5000nm. These are the Condensation Nuclei Counters (CPC), which enlarge the particles using a condensed fluid and allow for optical counting.

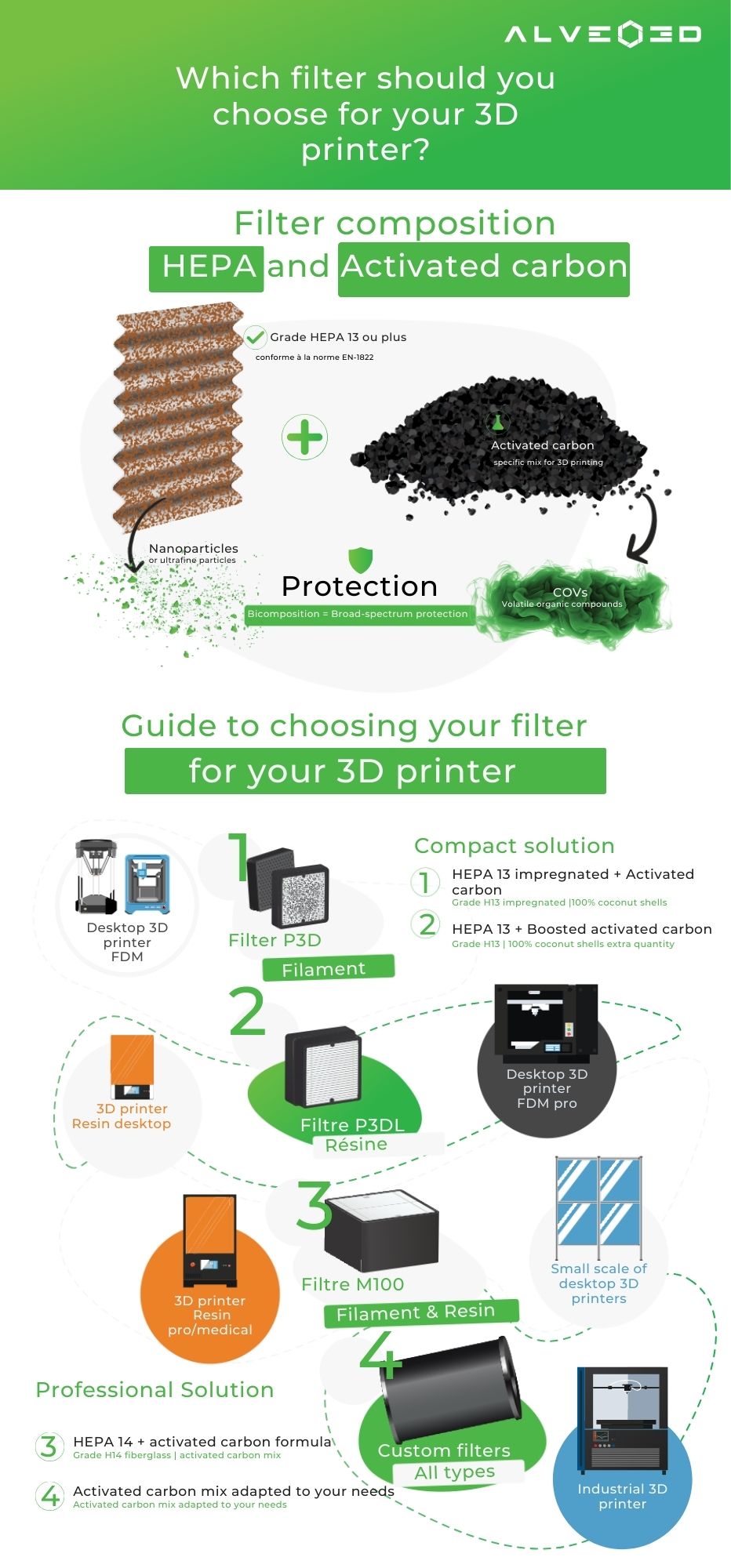

Our P3D filter is made up of a HEPA media and activated carbon. It was tested on a measurement bench to verify its ability to filter 3D printer nanoparticles.

The EN1822 standard defines the classification of filters through a classification of EPA, HEPA, and ULPA filters.

A certified filter guarantees performance for particles around 300nm. No guarantee is provided for particles smaller than 100nm, which is why we conduct additional measurements to confirm the effectiveness of filters with the pollutant emissions of 3D printers.

We have developed and built a measurement bench specifically dedicated to testing the performance of our filters. A 3D printer chamber enables the containment of all produced particles and measurement, before and after filtration, of the difference in concentration of nanoparticles through the intake duct.

II. What is the performance of the Alveo3D filter on 3D printer particles?

Considering that the HEPA 13 filter guarantees 99.95% efficiency at 300nm according to EN1822 standard, and that we mainly generate particles smaller than 100nm in additive manufacturing, it is necessary to test the filter’s performance more precisely.

We tested several types of H13 and H14 media. The Alveo3D team selected the one that offered the best balance between air resistance and filtering performance. Our P3D filter is equipped with a pleated H13 fiberglass media impregnated with activated charcoal.

The measurements revealed a minimum performance of 97.30% and a maximum performance of 99.44% on all particles up to 7nm. These results are very satisfactory for a HEPA media that is not necessarily effective for particles smaller than 100nm. The Alveo3D P3D filter, specially designed for 3D printing, provides good performance for filtering 3D printer nanoparticles.

III. Why is there a variation in filter performance?

The variation in performance is explained by the air flow of the filtration system, which will influence the speed of particle passage through the filter. A slower air speed allows the filter to capture more particles.

It is also explained by the size of the particles to be filtered, and the larger they are, the more effective the filter will be. The nature of the filament and the extrusion temperature will influence the dimension of these nanoparticles. Under these conditions, PLA will be less emitting than ABS.

IV. What happens when a 3D printer is used without air filtration?

We have observed very rapid increases in concentration on our measurement bench. This concentration remains high for a long period of time before returning to levels closer to atmospheric pollution.

When the enclosure is ventilated and filtered, these pollution peaks are eased, and exposure time is greatly reduced. This allows the 3D printer operator to quickly and safely access the interior of the enclosure through the P3D HEPA filter.