3D printer fume extractor | ALVEOPRO – M100

Certified and tested fume extraction system for 3D printers

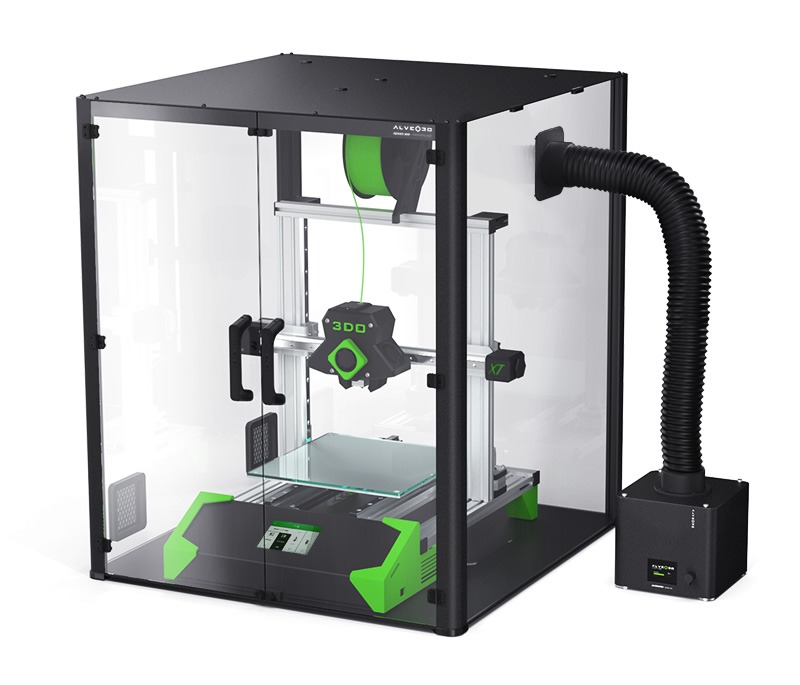

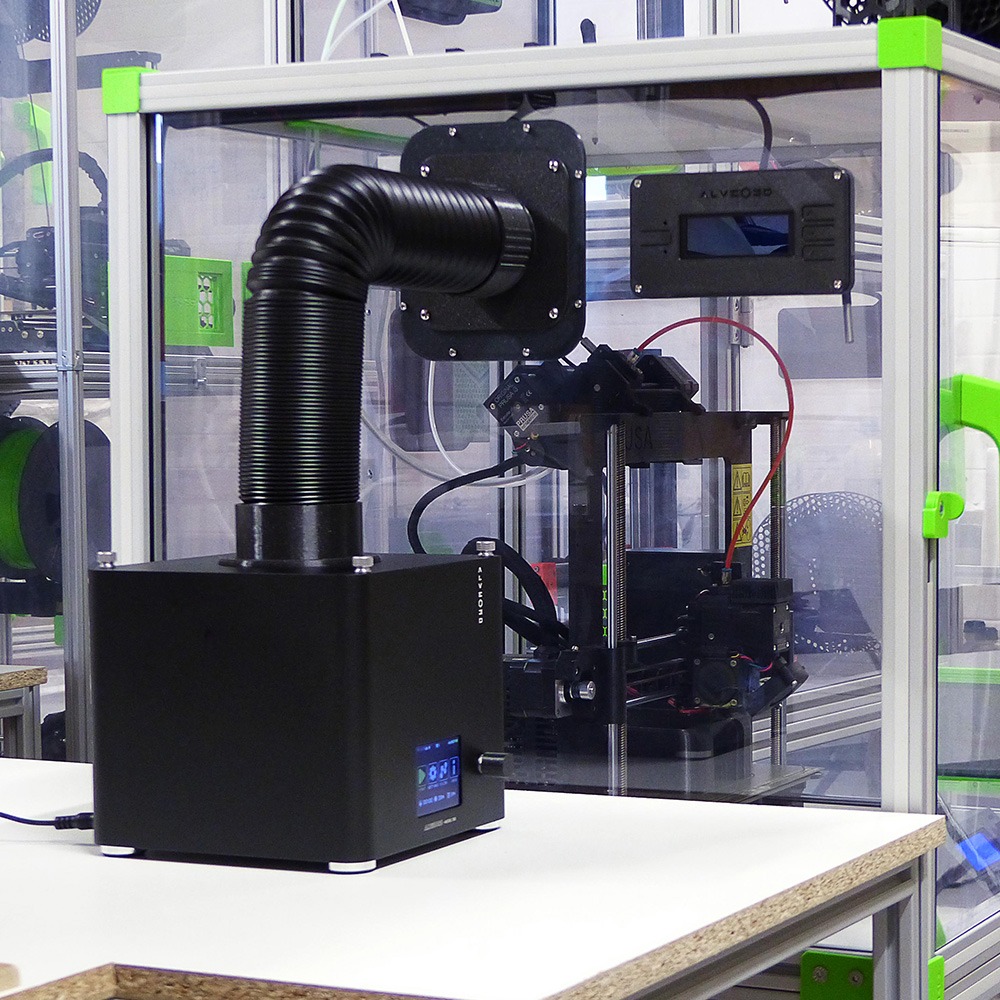

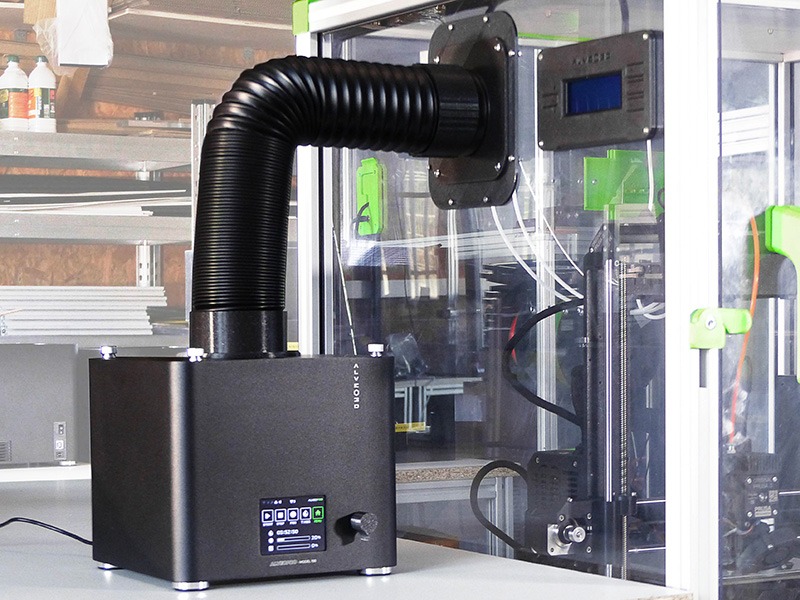

AlveoPRO professional 3d printer fume extractor combines the best assets to make 3D printing more efficient and safer. It can be adapted to all 3D printers or all printer enclosures thanks to its HEPA 14 filter/activated carbon and powerful suction system.

Designed and manufactured in our workshops in France, the AlveoPRO filtration system enhances 3D printing fume extraction, efficiently purifying the air from emissions produced throughout the printing operation, ensuring your workspace remains both clean and conducive to health. Here, all the functionalities are integrated into a single device that embeds an advanced electronic control.

Made in France

898,80€ Inc. VAT

Our clients trust us for their safety

Industrial quality and universal compatibility for professional 3D printers

3D printing fume extraction systems

AlveoPRO air filtering system

The AlveoPRO air filtering device offers the best efficiency in terms of harmful emission treatment from 3D printers. Provided with a high efficiency filter and a powerful suction fan, you will be able to print all your projects eliminating nanoparticles and VOCs without jeopardizing your printing process.

Learn more

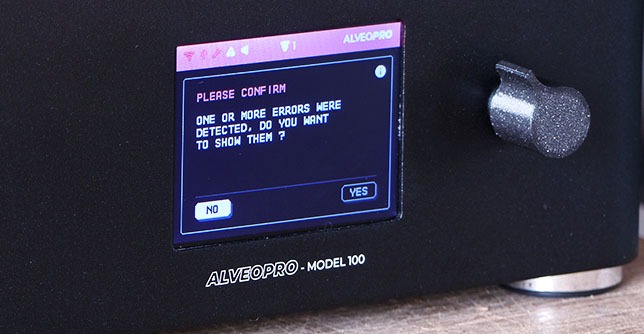

The addition of an LCD screen was an essential solution for the evolution of the structure. This new feature allows you to remotely control a range of customised settings including fan speed in order to promote more or less rapid filtration, the wear and tear of the 14HEPA activated carbon and glass fibre filter to monitor its saturation and anticipate its replacement, and the setting of an automatic timer to improve the filter lifespan.

The integrated safety system informs you at any time of a breakdown. This means you can quickly react to an anomaly and resume your printing pattern. The USB port also allows you to regularly update the firmware of the box.

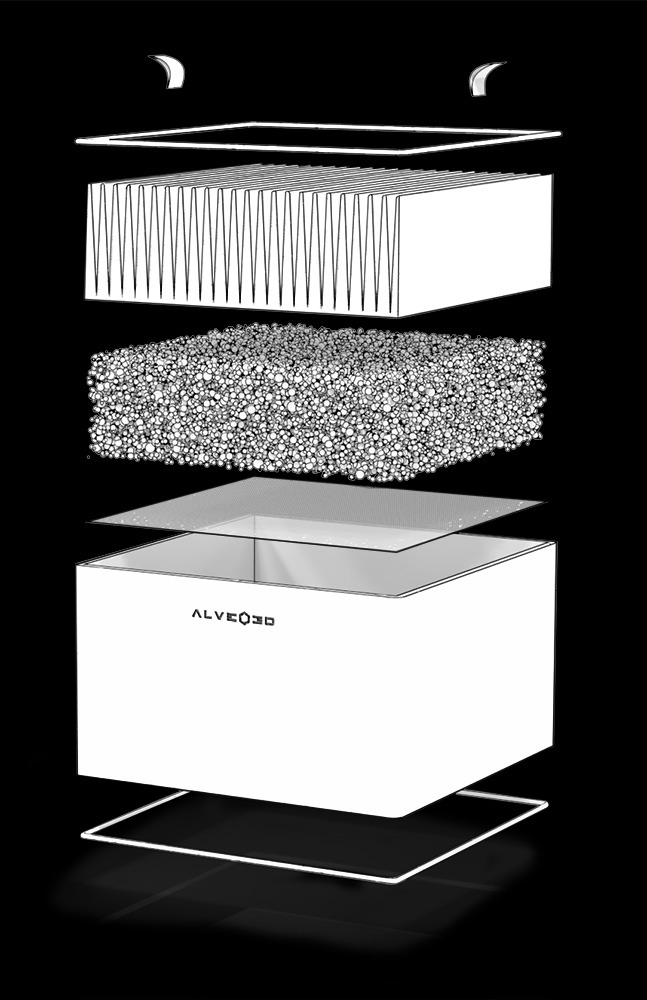

HEPA 14 filter for 3d printer fume extractor and activated carbon

M100 filter

Learn more

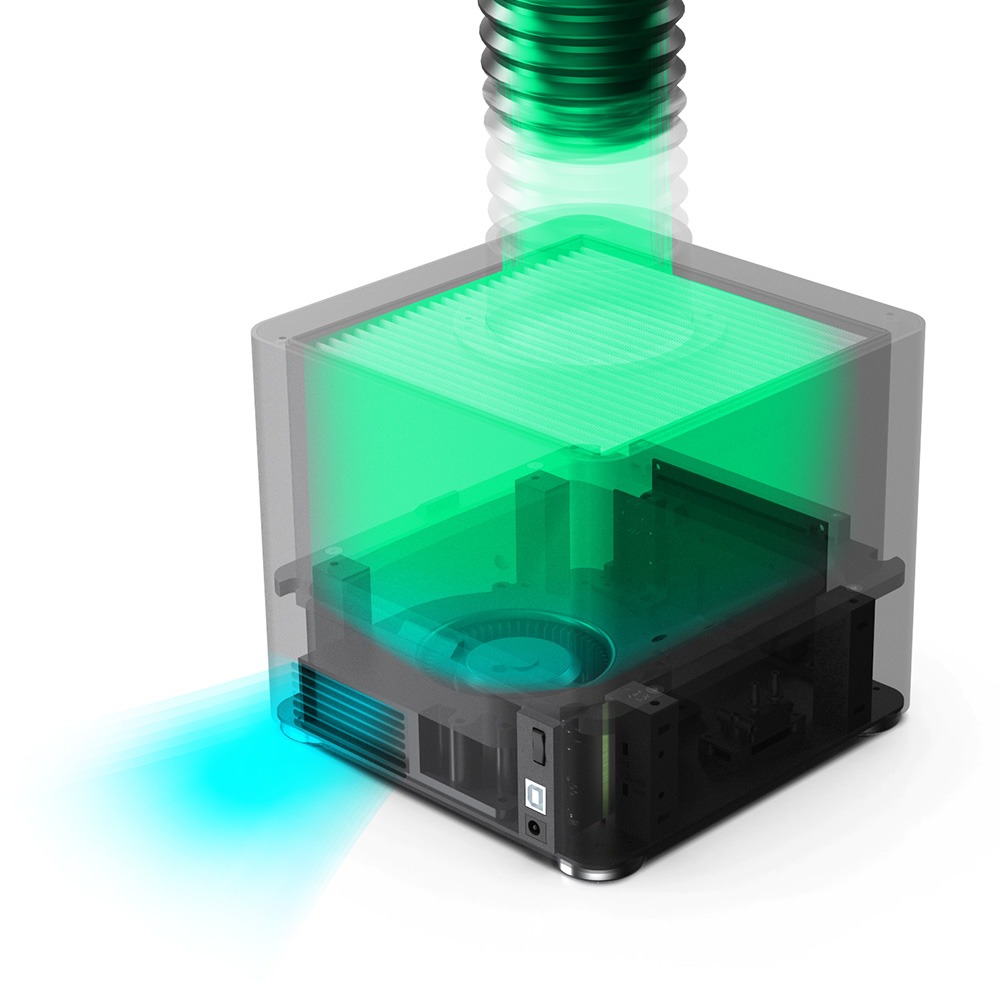

Activated carbon filters are small pieces of carbon, in granular form, which have been treated to be extremely porous. Its honeycomb structure allows these filters to absorb exponentially more contaminants and allergens than traditional carbon. Adsorption is a separate process where organic compounds in the air react chemically with the activated carbon, causing them to stick to the filter. The more porous the carbon, the more contaminants it will pick up. When air encounters the H14 HEPA filter, ultrafine or nanoparticles, and pollutants are trapped on its inner surface.

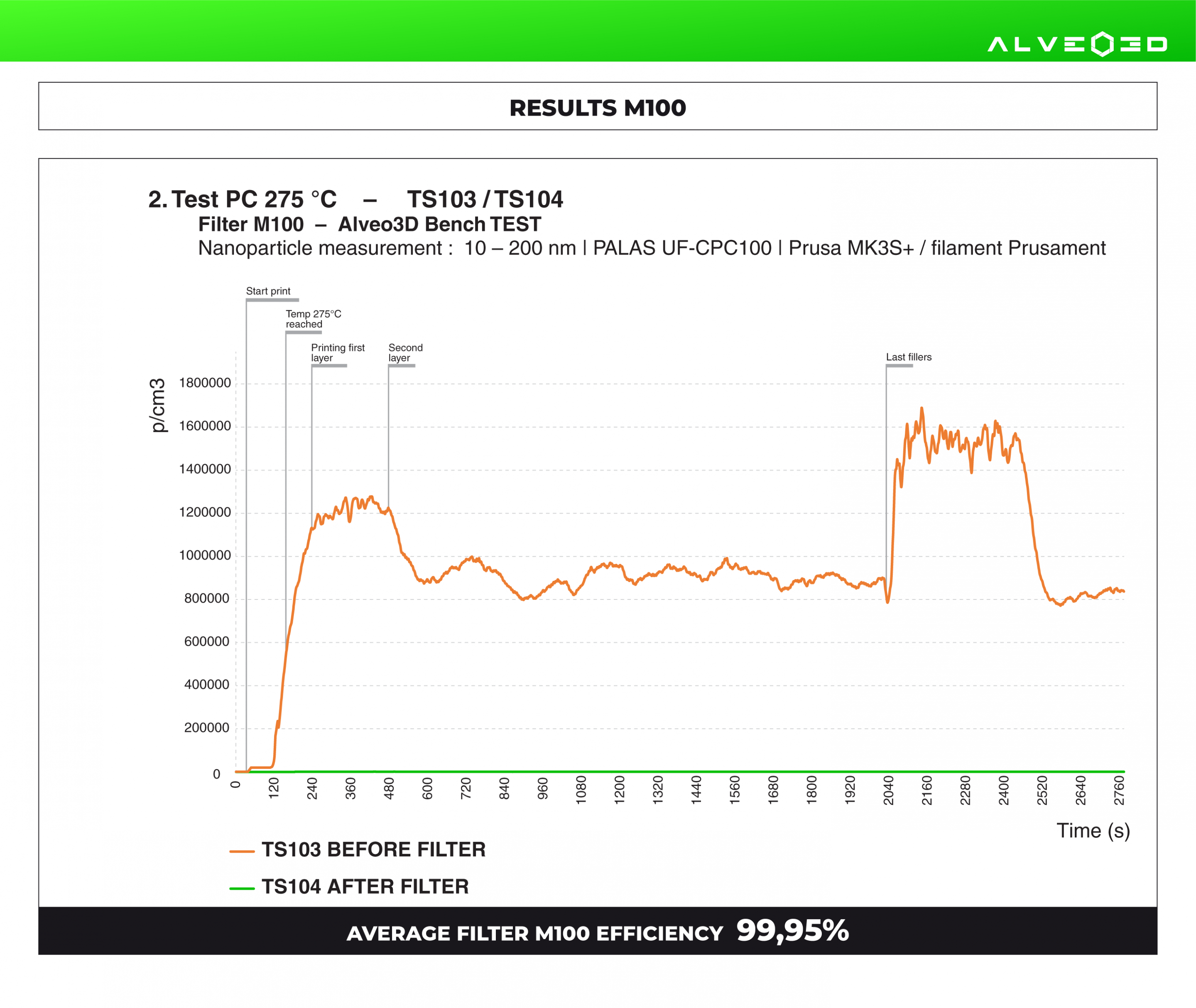

The efficiency of HEPA 14 (High-Efficiency Particulate Air) filters is governed by the EN 1822 standard which defines 5 efficiency classes. The HEPA H14 filter we offer has the highest filtration efficiency, stopping 99.95% of particles with a diameter greater than or equal to 0.3 µm.

Why to choose air filtering AlveoPRO ?

6 benefits for your additive manufacturing needs

Extended filter lifetime

At least 1500 hours of a lifetime for better productivity and simplified maintenance (replacement service)

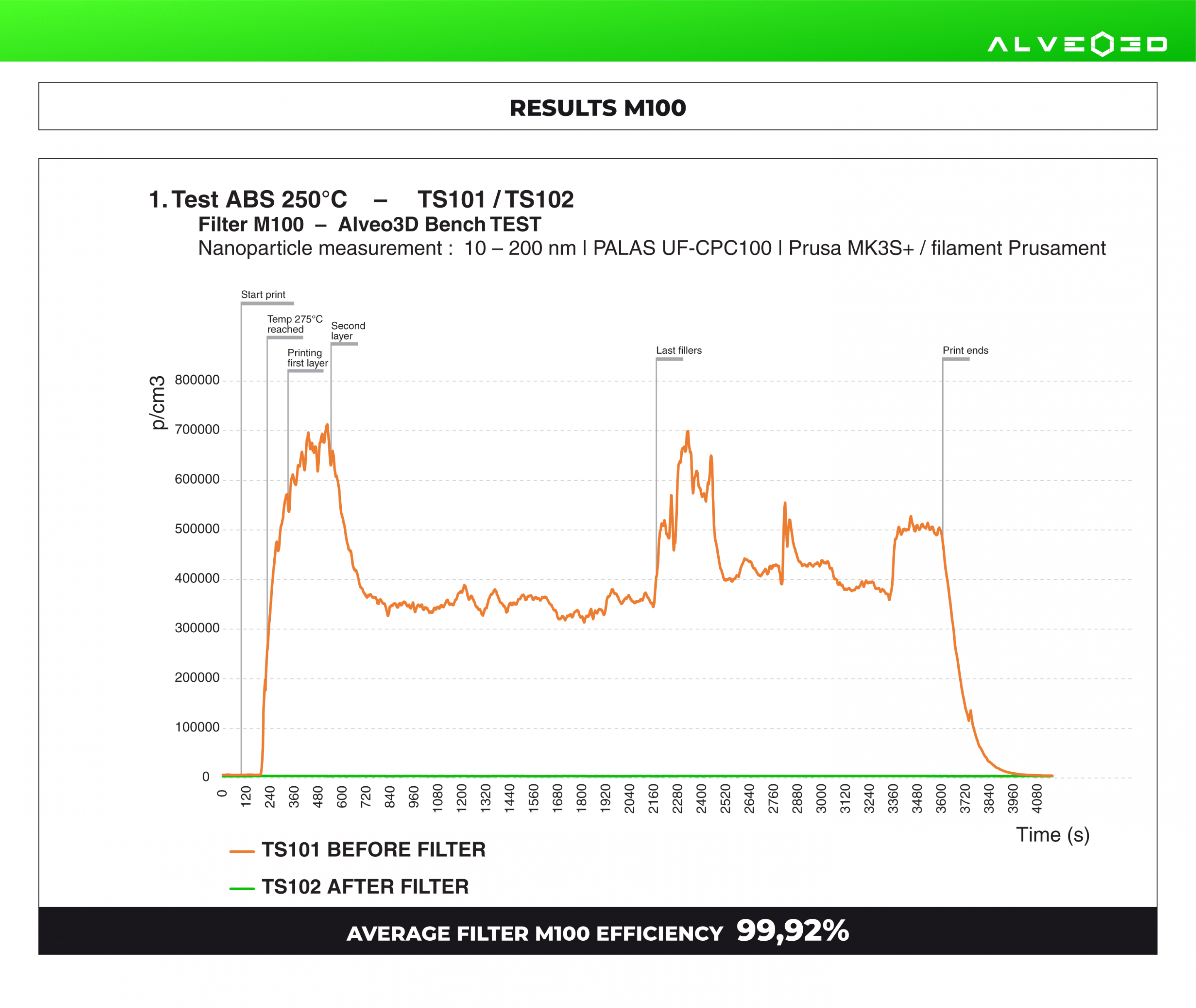

Extra filter efficiency

99.92% efficiency (tested) on nanoparticles from 10 to 200 nm emitted from FDM 3D printing.

Improve your 3D prints

Adjustable airflow from 10 to 80 m3/h to protect up to 4 nozzles (or 4 3D printers with a single nozzle) simultaneously.

Electronic safety and visual warning

Firmware update via USB

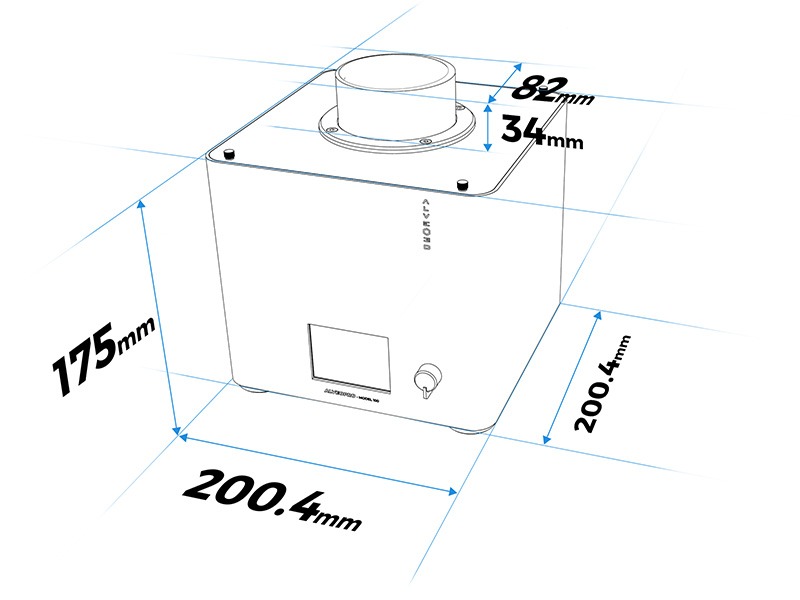

Light structure in aluminium

Compact design, tough and elegant for better integration in all work spaces.

Safety for nanoparticles and VOCs

Professional efficiency

3D printing generates many micro-particles that are harmful to the body. Because of their size, the particles can pass through the lung walls and go directly into the bloodstream and organs. By using an AlveoPRO box, you protect yourself from nanoparticles and volatile organic compounds that are harmful to your health.

Learn more

The AlveoPRO solution combines all necessary features to meet professional needs. Specific filters for 3D printers guarantee to be the ideal solution to resolve the risks of all nanoparticles and VOCs from 3D printers without lowering your productivity. Managing the airflow is essential for 3D printing, especially the warping effect. A constant airflow is generated by the AlveoPRO which can be adjusted between 10 and 80m3/h. You can be equipped with desktop 3D printers and also industrial 3D printers. You can adjust the air renewal rate for small to large printing volumes.

Compact

Light

Universal

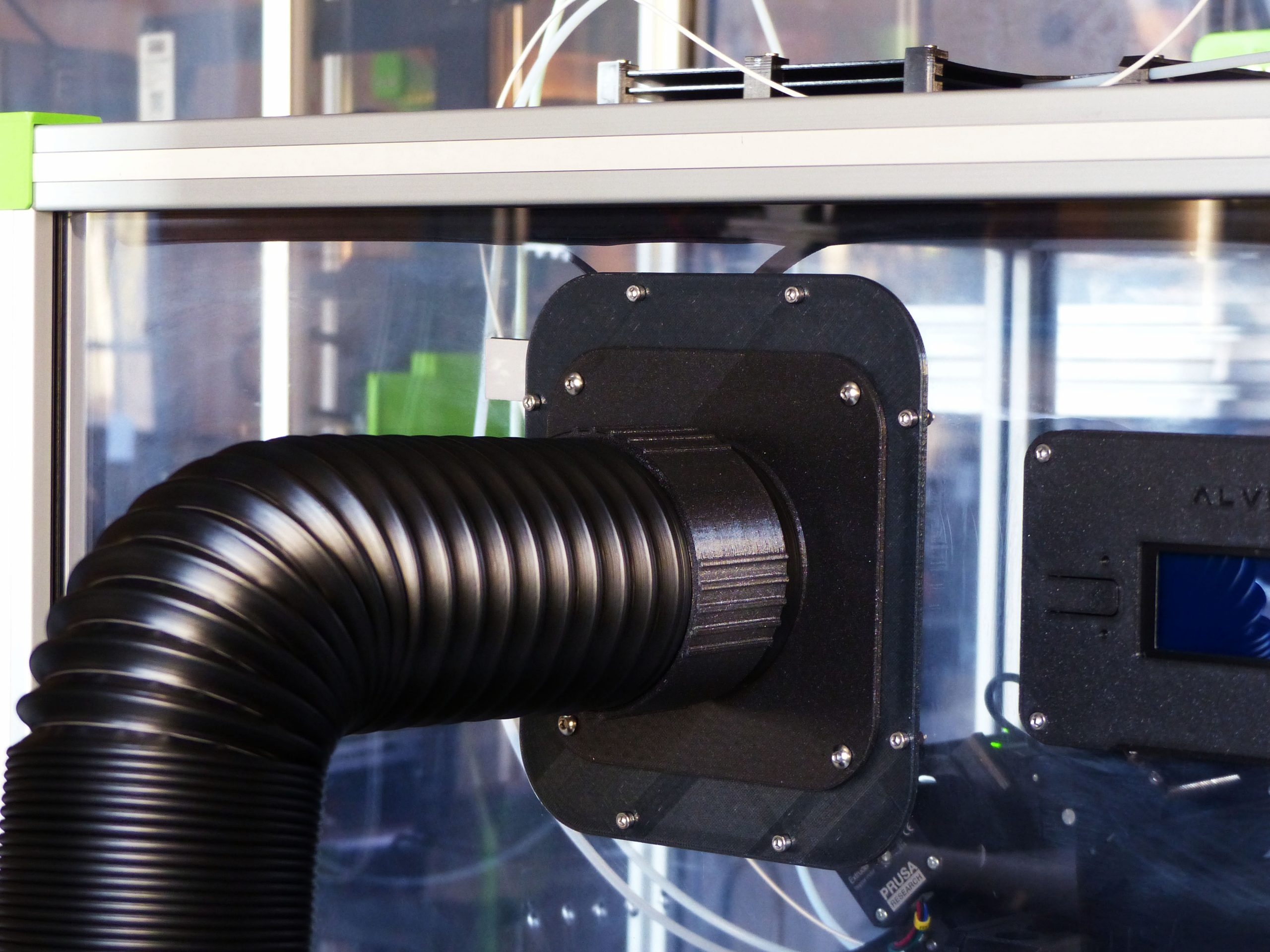

Mount on 3D printer enclosures

- Hose/ hose adapter provided : for 120mm / 90 mm fans

- File .step can be modified for perfect compatibility

- 3D modelling service for customized hose adapters

Don’t miss the advanced 3D printing fume extraction system

Embedded electronic features

PWM

Fan speed is adjustable according to print volume and the type of filament used to optimise printing results.

Timer

Filter

Safety alert

Update

Settings

Technical specifications

Dimensions

Package bundle

- 1. AlveoPRO case

- 2. Wall-mounted power supply 24V

- 3. Expandable suction hose 0,8m to 3m

- 4. Suction hose connection plate (for axial fans 120mm and 90mm)

- 5. M100 filter – Pleated fiber-glass HEPA 14 and optimised activated carbon for VOCs from 3D printing

- 6. 1500h lifetime

- 7. USB cable

- 8. Hexa key 2,5mm

- 9. Anti-vibration pads

Fan specifications

- 1. Air flow from 10 to 80 m³/h

- 2. Noise level: 40 to 60 dB

- 3. Suction from the top

- 4. Air outlet on the back side

- 5. Air inlet 80mm diameter

- 6. Expandable suction hose

Weight

M100 filter

HEPA & Activated carbon- 1. Pleated fiber-glass HEPA 14

- 2. Optimised activated carbon for FDM/SLA

- 3. Weight: 1.2 Kgs

- 4. Handles

- 5. Sealing cord on both sides

- 6. 1500+ hours of lifetime

Electronic features

*version 2022-01-02- 1. Display LCD 2,8″

- 2. PWM fan speed

- 3. Timer

- 4. Filter saturation controller

- 5. Customization options

- 6. Reset filter controller

- 7. Stand-by mode

- 8. Electronic safety : error detection and filtration issue monitoring

FAQ

Do I need a 3d printer fume extractor for my 3D printer?

This depends on several factors, including the type of filament you use (ABS, PLA, etc.), the size of your printer and enclosure, and your personal health concerns.

- Type of Filament: Different types of filaments emit different fumes when heated. For instance, ABS filament emits styrene, which can be harmful if inhaled in large quantities, while PLA filament is generally considered safe.

- Printing Environment: If you’re printing in a well-ventilated area, the fumes may dissipate quickly enough to not pose a significant risk. However, if you’re printing in an enclosed space or in a poorly ventilated room, fumes can accumulate and become a health hazard.

- Frequency and Duration of Printing: If you’re only printing occasionally and for short durations, the risk from fumes is lower compared to continuous and long-duration printing sessions.

- Personal Health Considerations: Individuals with respiratory issues or sensitivities may be more susceptible to the effects of 3D printing fumes and may want to take extra precautions.

- Type of Printer: Some 3D printers come with built-in fume extraction systems or enclosures designed to mitigate fumes. If your printer has such features, you may not need additional extraction.

What are the health risks of 3D printing fumes?

The health risks associated with 3D printing fumes can vary depending on the type of filament being used and the printing conditions. Some potential health risks include:

- Irritation of Respiratory System: Fumes emitted during 3D printing can irritate the respiratory system, leading to symptoms such as coughing, throat irritation, and difficulty breathing.

- Headaches and Dizziness: Exposure to certain 3D printing fumes, particularly from ABS filament, can cause headaches, dizziness, and nausea.

- Eye and Skin Irritation: Contact with fumes or particles released during printing may cause irritation to the eyes and skin.

- Allergic Reactions: Some individuals may be allergic to certain materials used in 3D printing filaments, leading to allergic reactions upon exposure.

- Toxic Fume Inhalation: Certain filaments, such as ABS, release potentially harmful volatile organic compounds (VOCs) and ultrafine particles when heated, which can pose long-term health risks if inhaled in significant quantities over time.

- Potential Carcinogenicity: Some studies have suggested that certain materials used in 3D printing, such as styrene emitted from ABS filament, may have carcinogenic properties. Prolonged exposure to such substances could potentially increase the risk of cancer.

How often do I need to change the filters?

The frequency at which you need to change the filters in a fume extractor system depends on several factors, including the volume of emissions, the type of materials being printed, and the operational hours of the printers. When considering environments with significant emissions such as dust or larger particles, these can indeed clog filters faster than VOCs or nanoparticles typically emitted during the 3D printing process.

We recommend you to change your filters:

- Activated Carbon Filters: You may need to replace activated carbon filters every 3 to 6 months, or sooner, if you notice a decrease in odor control or an increase in fume levels.

- HEPA Filters: It’s recommended to replace HEPA filters every 6 months, or sooner if they become visibly dirty or clogged.

Can a fume extractor AlveoPRO handle many 3D Printers?

Yes, a fume extractor AlveoPRO can handle multiple 3D printers (2 or 3 3D printers ideally), but the capacity to do so efficiently depends on several factors including the power and design of the fume extraction system, the volume of fumes each printer generates, and the setup of your printing area.

Factors to Consider:

- Extraction Power and Capacity: The fume extractor’s power and capacity to move air (measured in cubic feet per minute, or CFM) determine how effectively it can handle multiple sources of fumes. A system with a higher CFM rating can manage more printers simultaneously.

- Filtration System: The efficiency of the filters (pre-filters, HEPA filters, and activated carbon filters) in capturing particulates and gases is crucial.

- Placement and Ducting: Proper placement and potentially the use of ducting or hoses to direct fumes from multiple printers to the extractor are important for effective fume management.

- Type of Printers and Materials Used: The amount and type of fumes generated by different 3D printers and materials (e.g., ABS vs. PLA) can vary significantly. Printers using materials that emit more toxic fumes may require more powerful extraction solutions.

- Operational Considerations: If all printers are operating simultaneously and continuously, the demand on the fume extraction system will be higher than if the printers are used sporadically or in rotation.

Can a whole room with multiple printers filter fumes instead of enclosing each printer separately?

Yes, filtering an entire room rather than enclosing individual printers is feasible, especially for a setup like a 3D printer farm where parts automatically extract into bins. Such a system would typically involve industrial-grade air purifiers or HVAC integrations with HEPA and activated carbon filters to capture particulate matter and volatile organic compounds (VOCs) efficiently.

However, for AlveoPro, it’s designed for direct attachment to single printer ou 2 printers rather than providing room-wide filtration.

When considering room-wide filtration for a printer farm:

-

- Assess the Total Output: Calculate the total fume output based on the number and type of printers and materials used.

- Consider Airflow and Ventilation: Ensure the system can handle the room’s cubic footage and has adequate intake and exhaust capabilities.

- Look into Industrial Air Filtration Solutions: These are designed for larger spaces and can often be customized to specific needs, including automatic extraction systems.

- Professional Consultation: It’s highly recommended to consult with air filtration experts or HVAC professionals who can design a system tailored to your specific requirements, considering all safety and health regulations.

Get your AlveoPRO 3D printer fume extractor

The professional air filtering system for your 3D printer

KNOW HOW

FAST DELIVERY

Available in European countries

CONTACT

WARRANTY

2 years warranty for all

Reviews

There are no reviews yet.