3D printing has quickly moved from a futuristic idea to a practical tool in many industries. But safety is often an afterthought. This guide focuses on using 3D printing safely for food-related items, such as packaging, utensils, and even the food itself. We’ll look at which materials are non-toxic and clean enough for these purposes, helping industries integrate this technology responsibly

1. Understanding food safety regulations

The food safety regulations that are specific to your region and industry will, of course, provide the guiding principles to any 3D printing implemented within food processes. For EU countries, you’ll be looking to the Regulation (EC) No 178/2002 and the updated guideline 2010/2011. In the US, the FDA CFR 21 will act as the main point of reference.

These regulations are not light-reading, and for good reason. The following requirements are true wherever you are in the world regarding food safe materials:

- Materials must be corrosion resistant, durable and nonabsorbent.

- Accessible to inspection.

- Materials must not impart odor, color or taste.

- Must withstand repeated washing.

- Any material that comes involved in food production must have a sufficiently smooth, easily cleanable material without acute internal angles or breaks.

Source: Internet

Of course, the different regulatory guidelines have specific ways of measuring and assessing each of these criteria. However, this gives a solid idea of the regulatory requirements. Suppliers will have their own regulatory approvals, but it pays to do due diligence on your specific processes. Also, it’s possible that if you used 3D asset store, the assets will come with specifications on materials.

Therefore, you must exercise caution when selecting a “food-safe” 3D model from an online library, taking into account three crucial factors:

- Materials: The choice of material is fundamental, as not all materials used in 3D printing are suitable or safe for food contact. Materials should not only be non-toxic but also capable of withstanding the conditions under which they will be used, such as exposure to heat, moisture, or food acids without degrading or leaching harmful substances.

- Manufacturing Technology: The specific 3D printing technology used can affect the safety and suitability of the finished product for food contact. Some printing methods may leave small gaps or pores in the material that could harbor bacteria, making the object difficult to clean and sanitize properly.

- Usage: Consideration of how the item will be used is also critical. For instance, objects intended for single-use may have different requirements than those meant for repeated use. Factors like the ability to withstand repeated washing, exposure to different types of food, and the physical stresses of everyday use should be considered.

2. Choosing the right materials for printing

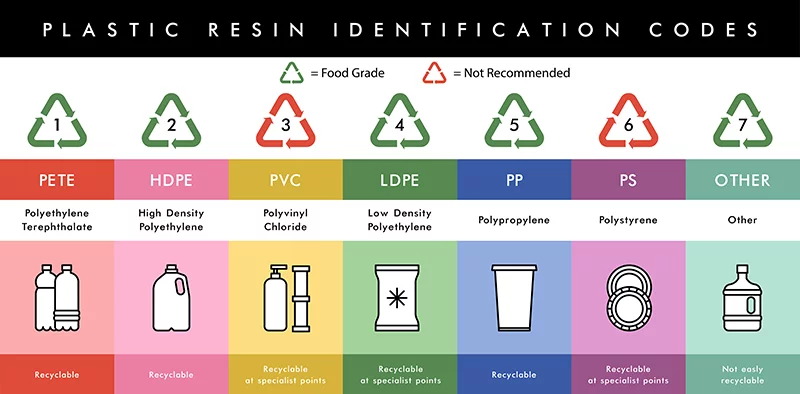

Not all plastics are suitable for food contact, and selecting the appropriate material before printing a model that will come into contact with food is crucial, as some can be extremely toxic.

Indeed, while certain polymers, such as PLA (Polylactic Acid), may be deemed food-safe, this does not imply that all PLA variants are suitable for food contact. The safety of the polymer depends not only on the base monomer but also on all other elements added to the material, including colorants, fillers, and any other additives. Each of these components must be evaluated to ensure they do not pose a risk when the printed object comes into contact with food.

Categories of substances authorized in plastic materials for food contact according to Regulation (EU) No. 10/2011:

- Monomers: These are the basic chemical building blocks from which polymers are formed.

- Additives: Substances added to modify or enhance certain properties of the plastic material, such as its color, stability, or resistance.

- Polymerization Auxiliaries: Substances used to facilitate or control the polymerization process.

- Colorants: Substances added to color the plastic.

- Solvents: Substances used to dissolve other substances during the plastic manufacturing process.

- Non-Intentionally Added Substances (NIAS): Substances that are not intentionally added to the material, but may be present due to contamination or chemical reactions.

- Nanoparticles: Nanometer-sized particles used to confer specific properties to the material.

- Dual-Use Additives: Additives that can be used in both plastics and other applications.

Source: Internet

When considering the production of food-safe 3D printed models, ensure the filament or resin adheres to regulatory standards. Formlabs provides a comprehensive overview on this topic, highlighting the compatibility of various processes and materials with food printing. Access this guide through their blog for detailed insights.

Yet, relying solely on materials labeled as food-safe is not enough to guarantee safety. The manufacturing process itself, including the cleanliness of the printer and the environment, along with post-processing techniques, must also be taken into account to ensure the final product is safe for contact with food.

3. Printing technology

With the above regulatory requirements in mind, let’s assess their suitability of the main 3D printing techniques, as well as the materials that are required for each.

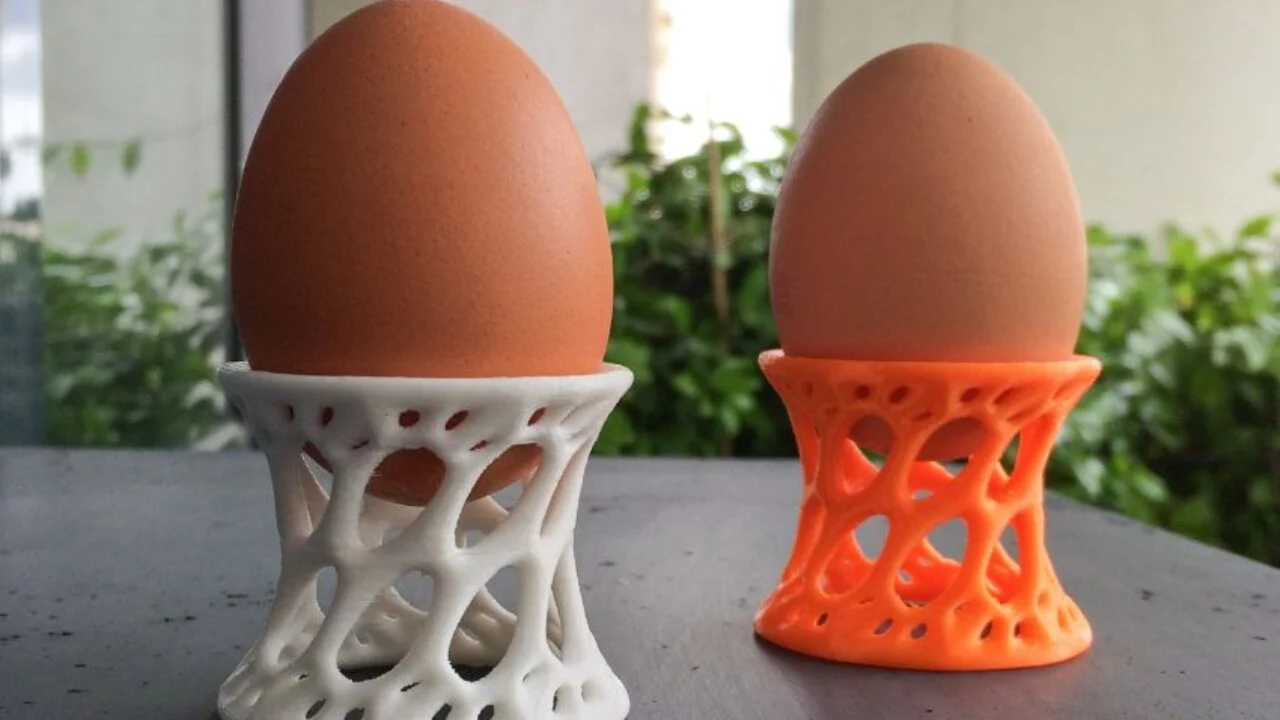

A. FDM

FDM is a relatively inexpensive form of 3D printing and is therefore an appealing prospect. However, FDM has certain disadvantages which are particularly troublesome when it comes to food production. (FDM poses specific challenges, especially in the context of food manufacturing.)

FDM works by extruding and melting thermoplastic filaments, which are then printed with a nozzle layer by layer. These layers then build up until the specified item is produced. However, as this process is reliant on stacked layers of printed material, there are unavoidable crevices between layers. While decreasing the layer height is an option to minimize this issue, it doesn’t entirely prevent the formation of cavities between layers.

So, the main problem with FDM in food production is bacteria buildup within crevices. This problem can be overcome with a mixture of chemical smoothing and applying a food-safe coating. However, this can add significant material and time costs to a production process, which need to be accounted for before making an investment in FDM printers.

Source: Internet

B. Stereolithography (SLA)

SLA is an expensive and, in many ways, more sophisticated form of 3D printing. It uses a laser or UV light to create hardened plastic from liquid resin. So, anyone looking to employ this method could find online library and rely on resin 3D models.

Though the resins used in SLA printing allow for very smooth surfaces, they are also inherently unsuitable to come in contact with food. That’s because most resins are toxic in both liquid and solid form and are prone to wear. So, as with FDM printing, it is necessary to apply a coating to any SLA printed item that is intended to come into contact with food.

C. Selective Laser Sintering (SLS)

SLS employs lasers to fuse polymer or metallic (DMLS) powders into 3D printed objects. Though many powders are food-safe, particularly the most common nylon powders, there is the chance that some of the surface area may remain porous. As such, it will probably be necessary to apply a food safe coating.

After reading about the complexities of achieving food-safe 3D printed models, you might conclude that there aren’t any viable solutions for printing models that are safe for food contact. Indeed, the current state of 3D printing technology might not be fully equipped to guarantee food safety for such applications. Prusa’s insightful article sheds light on the challenges and considerations involved in making 3D printed models food-safe. It suggests that if you’re determined to experiment with food-safe 3D printing, opting for the FFF (Fused Filament Fabrication) process might be more advisable than using resin or powder-based methods.

In this context, the PRUSA RESEARCH team has written an article about the process of creating 3D printed models of food-grade quality.

Despite the fact that most resins and powders are toxic in both their liquid and solid forms, objects produced by manufacturing methods like SLA easily deteriorate (forming a fine powder on the surface). There are several dental or low-odor resins available, but they are intended for very specific uses and are quite expensive. Here comes the main topic of our article, how to use a food-safe plastic product (3D printed or not) to keep it safe!

Source: Internet

4. How to use food-safe plastic

Using food-safe plastic, whether it’s a product you’ve 3D printed yourself or acquired commercially, requires understanding and adhering to certain guidelines to ensure it remains safe for food contact. The key to maintaining the safety of these plastic items lies in their proper use, cleaning, and storage.

Not all food-safe plastics are created equal, especially when it comes to their resistance to temperature. High temperatures can cause some plastics to break down and potentially release harmful chemicals or microplastics into food. For instance, plastics not designed for high heat can degrade when used in microwaves or ovens, leading to both structural and chemical deterioration.

Microwave Use: The microwave-safe symbol is a key indicator that a plastic product can be used safely in a microwave. This symbol means the plastic has been tested to ensure it can withstand microwave heat without melting or releasing harmful chemicals. However, even microwave-safe plastics should be used with caution, as overuse or heating beyond recommended times can still lead to degradation.

The breakdown of plastic in any form can lead to the release of microplastics, tiny plastic particles that can end up in our food and water. This is a growing concern for environmental and human health, as microplastics can carry toxic substances and contribute to pollution.

Source: Internet

5. Microplastics released from food containers.

In the pursuit of safe and sustainable food packaging solutions using 3D printing, the issue of microplastics released from containers appears as a major concern. Food containers made of certain materials, particularly plastics, have the potential to release microplastics into stored food over time, especially when exposed to heat or acidic content. These microplastics have risks to human health, with potentially harmful effects.

According to the studies of National Institutes of Health (NIH), there is rising worry over the use of plastic products in heat applications, with millions of micro- and nanoplastic particles produced from plastic food packaging when subjected to high temperatures.

Our findings further show that released PET nanoparticles can be easily swallowed by Marine macrophages, resulting in decreased lysosomal activity and implying negative impacts on cellular functioning.

Studies have also shown that Microplastics have been found in tests to alter the endocrine system, acting as estrogen in the body and causing difficulties such as delayed puberty in boys and early puberty in girls. Substances often present in plastic, such as benzotriazole UV stabilizers and bisphenol A (BPA), can mimic estrogen and cause hormone changes. Even BPA-free plastics may contain estrogenic compounds, which can be more potent than BPA. Avoiding exposure to microplastics is critical to mitigate these health hazards, as they can be present in a variety of daily products and potentially influence.

Over time, all plastics can deteriorate, especially with repeated exposure to harsh conditions like high temperatures, abrasive cleaning, or acidic foods. Signs of wear, such as scratches, cloudiness, or cracks, can indicate that it’s time to replace the item, as these imperfections can harbor bacteria and lead to the release of microplastics.

Source: Internet

6. 3D printing in the food industry

There’s no stopping the tide of 3D printing. Though production and manufacturing managers the world over may wince at the work involved in incorporating new technology, there’s no denying that 3D printing is fast becoming the fastest and cheapest means of food production.

For now, the final word on 3D printing in the food industry is that it is not practical to produce the smooth surfaces that are required. However, post-processes can bring 3D printed surfaces up to spec. Specifically, by applying coatings, manufacturers can 3D print materials that could meet regulatory requirements.

You can already buy 3D models for printing, but hopefully as 3D technology continues to develop, it is likely that it will become possible to purchase food print models or recipes to make with your 3D printer.

Enjoy printing safely 😉 !